Waterstone Upkeep

For the sharpest tools, keep stones wet and flatten them often

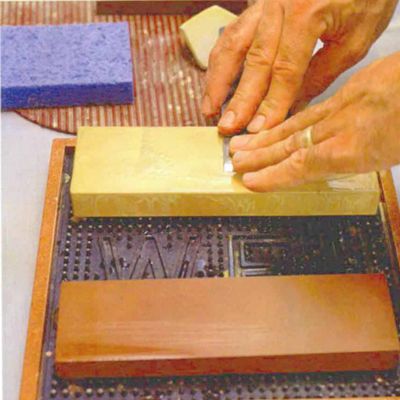

Synopsis: William Tandy Young says waterstones cut more quickly and efficiently than oilstones, and the finish they leave on a tool’s edge is more consistent. He uses synthetic waterstones, and explains why he prefers them. He talks about getting the stones ready, how to store them, and the benefits of establishing a dedicated sharpening station in your shop. He also explains how to flatten stones and how to sharpen your tools with them.

I wouldn’t want to work wood without sharp tools, and I sure wouldn’t sharpen them with anything but waterstones. Waterstones cut more quickly and efficiently than oilstones, and the finish they leave on a tool’s edge is more consistent. The feedback they provide is tactile and immediate. I can feel the waterstones abrading the steel as I hone, and I know what kind of edge I can expect from each stone that I have.

I use the commonly available synthetic waterstones, as opposed to the natural waA dedicated sharpening station makes sharpening less of a chore. The convenience of having an area specifically for sharpening will take much of the hassle out of the process. And it doesn’t have to be pretty: Scrap materials work just fine. terstones. The synthetic stones, which make up more than 99% of the waterstones sold in this country, are sold under such names as King, Dragon, Deluxe, Bester, Aquastone and Debado. These stones differ in composition and in the processes by which they’re made, but generically speaking, they’re all combinations of abrasive minerals (such as aluminum oxide or chromium oxide) in a matrix, or binder, of ceramic material.

Natural stones, besides being generally more expensive (sometimes extravagantly so), also need to be treated differently. Most importantly, perhaps, natural stones should not be stored in water, or they could crack and eventually decompose. So for the purposes of this discussion, I will talk about the synthetic stones that I use and am familiar with.

Waterstones belong in that select group of tools whose actual performance is as good as the claims and fanfare that precede them. If you don’t believe that, try talking to a woodworker who’s switched from oilstones to waterstones. But waterstones don’t work magically; using them effectively requires care and practice.

My first attempts at honing with waterstones were erratic and messy, and I found myself spending more time maintaining the stones than using them. Ultimately, though, I developed a sound technique. Working with waterstones is now a delight; I can sharpen my tools quickly and consistently, which in turn helps make hand-tool use a more fluent and vital practice in my shop. Here’s a basic overview of how I have come to integrate the storage and maintenance requirements of synthetic Japanese waterstones into my shop space and routine.

From Fine Woodworking #111

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Veritas Micro-Adjust Wheel Marking Gauge

Starrett 12-in. combination square

Stanley Powerlock 16-ft. tape measure

Log in or create an account to post a comment.

Sign up Log in