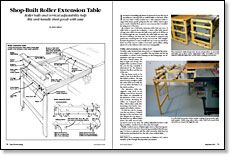

Shop-Built Roller Extension Table

Roller balls and vertical adjustability help this unit handle sheet goods with ease

Synopsis: A detailed project plan kicks off this quick article by Bob Gabor, who designed a fold-away extension table that uses rows of roller balls to support workpieces. He explains why he uses balls instead of tubes, and how his table provides both utility and economy. He added levelers to the leg assemblies and a piece of lightweight chain to limit the leg travel.

I was tired of wrestling big sheets of plywood across the top of my tablesaw. I already had an outfeed table on the back of the saw, but what I really needed was a side extension table to support the heavy panels going into the saw. I didn’t want to give up too much valuable floor space to an accessory that I wouldn’t be using most of the time.

My solution was a fold-away extension table that uses rows of roller balls to support the workpiece. I chose roller balls instead of long, tube rollers because the balls won’t pull stock off-line as it is fed through the saw. Normally, the roller balls are even with the saw’s tabletop, but they also can be raised to support long panels that overhang the end of my crosscut box. This straightforward shop fixture is easy to build and use. It sets up and drops back out of the way in a matter of seconds, and it makes cutting plywood on the tablesaw safer and more manageable.

Utility and economy in a shop tool

I’d rather make furniture than shop tools, so I designed the extension table to be as simple as possible. The top frame and the leg assemblies, as shown in the drawing on the facing page, are inexpensive and easy to assemble with a biscuit joiner. Yet they’re light and strong. The length of the top-frame assembly and the leg assembly is determined by the distance between the floor and the top of the saw.

The top frame needs to be sized to just clear the floor in the folded position. The legs must be long enough to make the roller balls level with the saw top when the frame is in the raised position.

The extension table also supports long stock in my sliding crosscut box because the rollers are adjustable by the thickness of the crosscut box’s bottom. Mounting the rollers on T-shaped assemblies, which adjust easily after loosening a few knobs, was a simple and reliable solution.

From Fine Woodworking #112

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Double Sided Tape

Incra Miter 1000HD

Dividers

Log in or create an account to post a comment.

Sign up Log in