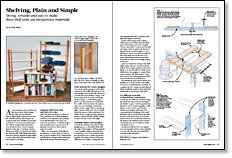

Shelving, Plain and Simple

Strong, versatile and easy to make, these shelf units use inexpensive materials

Synopsis: M. Felix Marti explains how to make inexpensive, lightweight, sturdy shelves that use simple joinery. He uses plastic laminate glued to both sides of medium-density fiberboard or particleboard, and cuts tight-fitting dado joints with the uprights at right angles. He laminates the shelf stock first, then cuts it to size. He dadoes the material for the corner uprights and then assembles the shelves. He talks about different materials to try and knockdown construction methods, too.

As unassuming as these shelves are, they have many of the features that I like most in furniture. They’re lightweight, sturdy and use simple, effective joinery. The design I use evolved partly from childhood memories of shelves in our house and partly from the built-in storage-shelf system that I now install in houses. Plastic laminate glued to both sides of medium-density fiberboard (MDF) or particleboard makes the shelving stiff. Tight-fitting dado joints and front and rear uprights at right angles to each other make the assembly strong and resistant to racking.

Laminate shelf stock first, and then cut to size

I glue the plastic laminate to a sheet of 5 ⁄8-in. particleboard or MDF. Melamine could be a less-expensive and, perhaps, a less-stiff alternative, but I have not used it for my shelves. A cabinet-component manufacturer is a good source of laminated stock if you don’t want to make it yourself.

With a new shopmade throat plate in my tablesaw, I cut the shelves to size using a Forrest Duraline HI-A/T blade made specifically for cutting double-sided laminated stock. There is virtually no chipping on the down side of the shelf stock.

Dado material for corner uprights

I lay out the shelf spacing on a 9-in.-wide oak board. This width will yield four 2-in.- wide upright corner posts with allowance for kerfs and some cleanup. Using a 1 ⁄2-in. down-shear bit in my router and the jig shown in figure 1 on the facing page, I plow 1 ⁄4-in.-deep dadoes across the full 9-in. width. The down-shear bit makes a clean cut, and careful jig construction yields a dado so tight I have to tap the uprights onto the shelf stock. Then I rip this board into pieces a little wider than 2 in., which I feed on edge through a planer to produce uniform finished widths. Finally, I round over the corners and edges.

Assemble shelves and uprights

I now fit the shelf into the dadoes of the upright pieces, so the shelf is flush with the edge of the upright. I drill through the corner uprights using a tapered bit and counterbore. I use a 2-in. particleboard (not drywall) screw to fasten the pieces together. The deeper thread of the particleboard screw makes a strong joint.

From Fine Woodworking #113

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Suizan Japanese Pull Saw

Veritas Standard Wheel Marking Gauge

Festool DF 500 Q-Set Domino Joiner

Log in or create an account to post a comment.

Sign up Log in