No-Hassle Panel Handling

Moving and storing sheet goods doesn't have to be backbreaking labor

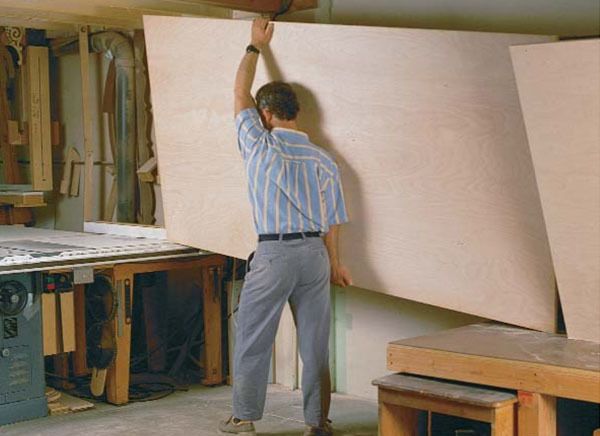

Synopsis: Moving sheets of plywood, melamine or medium-density fiberboard is a backbreaker. Skip Lauderbaugh has no forklift, so he came up with ways to handle big sheets easily. He can now unload, store, sort and move panels to the saw using little effort, by himself, using a low platform, saving labor, space, and time. He shows how his system works and the material that went into building the platform, the adjustable bolsters, the cutoff racks, and the roll-out assembly tables. The platform is 6 ft. from his saw and has hand-width cutouts for grabbing the sheets. Bolsters hold the sheets as he leafa through your supply.

When you need big, flat panels that are stable, smooth and ready to be cut, you just can’t beat sheet goods. But moving plywood, melamine or medium-density fiberboard (MDF) is a backbreaker. A single 4×8 sheet of 3⁄4-in. MDF weighs almost 90 lbs., and it’s terribly awkward to maneuver, especially by yourself.

I used to think that schlepping panels by hand was a necessary evil in my cabinetmaking business. Like many small-shop owners, I didn’t have the space or the budget for material-handling equipment like a forklift. I stored panels near my saw in a stack. But it seemed whichever panel I wanted was always buried at the bottom of the pile. The day I needed a panel that was under 30 sheets of melamine, I just knew there had to be a better way.

It was time to stand back and analyse my entire panel-handling process—from unloading the truck to pushing panels through the saw. My goal was to devise a way for one person to unload, store, sort and move panels to the saw, using the least possible effort. So I came up with a storage system built around a low platform.

Panel-storage system saves labor, space and time

When I began studying how I had been moving sheet goods, I realized how inefficient I’d been. So I designed a panel-storage system to achieve five basic objectives:

- provide easy access to panels

- minimize lifting of entire sheets

- work at safe, comfortable positions

- organize panel cutoffs

- make the most of my floor space

At the heart of the panel-handling system is a 4-ft. by 10-ft. platform. The top of the platform is 24 in. above the floor, which is easy on the back for those rare times that I have to lift an entire sheet. The top is also at the right height for sliding sheets directly off the tailgate of my truck. And by standing on the platform, I can leaf through panels or reach up to my overhead cutoff rack. Connected to the top are two panel supports (I call them bolsters) that slide in tracks. The bolsters can be removed for loading panels or adjusted to fit the stack of sheets as it grows or shrinks.

From Fine Woodworking #114

For the full article, download the PDF below:

Fine Woodworking Recommended Products

AnchorSeal Log and Lumber End-Grain Sealer

WoodRiver Router Bit Storage Case

DeWalt 735X Planer

Log in or create an account to post a comment.

Sign up Log in