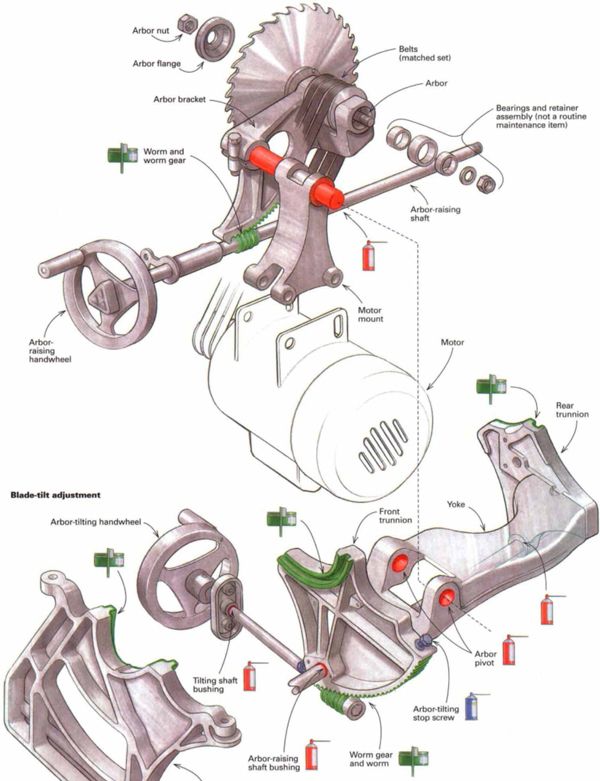

Synopsis: As the months and board feet of wood slide by, the once silky-smooth operation of Kelly Mehler’s tablesaw starts to take more muscle. Eventually, it’s time for a tune-up. Mehler explains tablesaw anatomy and breaks down tablesaw tune-up into steps: removing the top, cleaning the interior and arbor assembly, cleaning and lubricating the trunnion assembly, and replacing the top and aligning it. Mehler, who has written a book on tablesaws, is an expert on adjusting the motor and tensioning the belts. A color diagram shows precisely where lubricants are applied.

Several times a day, dozens of times in the course of a week, I crank the handwheels to adjust the blade on my tablesaw. Each time, the smooth, precise response from this otherwise ordinary task gives me a brief sense of satisfaction— things are okay. But as the months and board feet of wood slide by, the once silky-smooth operation starts to take more muscle. Eventually, tugging on the handwheel raises the blade in intermittent jerks, and tilting the blade provokes a metallic squeal. My saw is telling me it’s time for a tune-up.

The tablesaw is the most important power tool in my shop. Accurate and heavy, it’s built for the long haul. But it’s easy for me to take it for granted. I routinely check the cutting accuracy, but I don’t have a schedule for servicing internal parts. The cabinet base, valued for its stability, noise reduction and dust containment, shrouds the motor and internals—out of sight, out of mind. So, even though I know that cleaning and lubrication keep the saw in top shape, it’s only when I notice stiffness or noise while raising or tilting the arbor that I’m finally prodded into action.

The frequency of maintenance depends on how, and how often, the saw is used. Cutting abrasive materials, such as particleboard, Masonite and Formica, will increase the wear on internal parts. Sawing plenty of gummy, resin-rich or green wood creates pitch buildup. In my shop, internal parts should be cleaned and lubricated about once a year, and I set aside at least half a day to do it.

Tablesaw anatomy

It’s a lot easier to maintain your tablesaw if you have the original instruction manual and the parts list. All of the machine’s parts usually are shown as they would be assembled, which can be especially helpful when doing repairs and replacing parts. If you don’t have a manual and parts list, ask for one. Most manufacturers will oblige if you give the name, serial and model number of your saw. Manufacturers’ addresses can be found in the Thomas Register at your local library.

The drawing at left shows the guts of a typical cabinet-base tablesaw. The arbor assembly is the heart of the saw. It’s a structural casting, with integral worm gear, that houses the sawblade drive shaft (the arbor) on a set of bearings. In addition, the motor, motor mount, belts and pulleys also are part of this assembly. The trunnion assembly, also with an integral worm gear, supports the arbor assembly and allows the whole unit to tilt about the two arc-shaped slides, which are called trunnions. They engage mating brackets mounted to the front and rear of the cabinet.

From Fine Woodworking #114

For the full article, download the PDF below:

Fine Woodworking Recommended Products

JessEm Mite-R Excel II Miter Gauge

Freud Super Dado Saw Blade Set 8" x 5/8" Bore

Grizzly G0495X Industrial Helical Cutterhead 8-in. Jointer

Log in or create an account to post a comment.

Sign up Log in