Using Pneumatic Fastening Tools

These shop workhorses are fast, accurate and versatile

Synopsis: Nail-gun convert Robert M. Vaughan has learned to appreciate pneumatic guns. They leave no marks, inject nails into the wood (breaking fewer wood fibers and thus holding better), and they leave a hand free to hold the work. He explains here how they work, how to wade through the catalogs of them and choose one, and how to select nails, brads, and staples. He addresses safety issues and talks about how to shoot fasteners. He discusses other equipment you’ll need (air compressors), and how to lubricate and maintain nailers. There are things that can go wrong, and he offers advice on how to fix them. Side information talks about all the ways pneumatic nail guns help around the shop, and which nail guns different woodworkers, from Philip C. Lowe to Norm Abram, use in their shops and for which jobs.

I cringed the first time I saw a nail gun. It was 20 years ago, and my boss was comparing finish nails hammered and set by hand to the same-sized fasteners driven by a pneumatic (pressurized air) gun. I changed my mind, though, after seeing how quickly the nail gun did the job and how accurately and cleanly the gun drove the nails. It left no ugly hammer dents on the wood—elephant tracks, as I call them. And the nailer could be used one-handed, leaving the other hand free to hold the work.

The most convincing part of the boss’s impromptu demonstration was seeing that the air-driven nails stayed in the wood better than the hand-driven nails. A hammered nail breaks wood fibers each time it is struck, which reduces its grip. But an air-driven nail is injected into the wood all at once, which disturbs fewer fibers. The nail grips all the way up its shank. Guns drive nails with less splitting because the tips of the nails are like blunt chisels (see the photo at right). The ends of common finish nails are sharply pointed, so they tend to cleave the wood, causing splits. You can blunt the ends beforehand, but that’s a time gobbler.

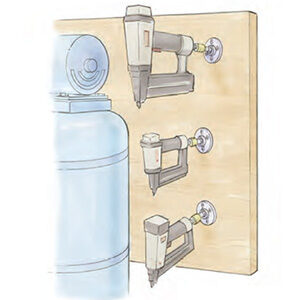

Early nail guns were used mostly in professional shops. These days, just about any shop can use one. You can pick up a good brad nailer for around $200. I’ve managed to accumulate nine pneumatic fastening tools and use one in nearly every project I do. And these tools are widely available from building-supply dealers, hardware stores and by mail.

How pneumatic drivers work

With one exception, all pneumatic nail and staple guns are powered by high-pressure air. Fasteners are driven by a rod or blade connected at one end to a piston in an air cylinder. When a gun’s trigger is pulled, air flows to the back of the cylinder, which drives the piston/driver assembly forward. The trigger is a two-way valve, so when it is released, a shot of air is diverted to the front of the cylinder. The air recycles the piston/ driver to the rear of the cylinder, so it’s ready for another shot. Usually, the internal air chambers are sealed with rubber O-rings.

From Fine Woodworking #114

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Milwaukee M12 23-Gauge Cordless Pin Nailer

Festool Cleantec CT 26 E HEPA Dust Extractor

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in