Using a Hollow-Chisel Mortiser

One man's techniques for a machine vital to his craft

Synopsis: John W. West’s business often tackles limited production jobs, where he says he’d be lost without his manual, foot-operated hollow-chisel mortise machine. It’s easy to set up for angled or canted mortises, and it’s the only type that will make a single square hole, like those in window-sash bars and louvered doors. West explains how it works and how to set it up and troubleshoot it. You should plan your joints first, and mark them precisely. He explains how different plunge methods vary and how to make them, and he details benchtop mortisers, too. Side information discusses how to sharpen hollow chisels.

Some time ago, fresh out of school, I practiced architecture for several years. I discovered early on that I had to make too many compromises to practice my trade. Now I own and run a small custom woodworking business, and I’m often awarded jobs that demand we make things in limited production quantities. It’s not unusual to get an order for two or three dozen large doors or to do a kitchen requiring 50 to 60 cabinet doors. For these jobs, I’d be lost without my mortiser.

I use a manual, foot-operated hollow-chisel mortise machine. There have been times when I would have appreciated the brute strength and speed of a pneumaticoperated chain or oscillating mortiser. But the one I use will produce a square-bottomed, square-ended mortise. It’s easy to set up for angled or canted mortises, and it’s the only type that will make a single square hole, like those in windowsash bars and louvered doors.

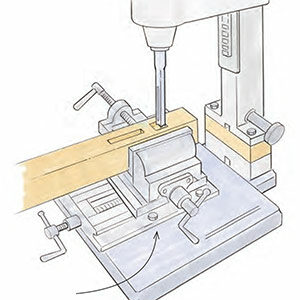

With a little ingenuity and some jig making, the hollow-chisel mortise machine will handle any angle or curve. I’ve used mine for cabinet face frames, chairs and benches, curved windows, lock sets, miniature fretwork and 10-ft.-high by -in.-thick doors. I could cut mortises by hand or use either a drill-press attachment or one of the benchtop mortisers that have come onto the market in the past few years (see the photos at right). Neither of those would do the job as quickly or as accurately, but they are options.

How the tool works

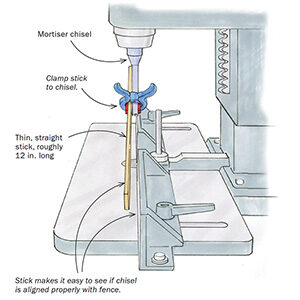

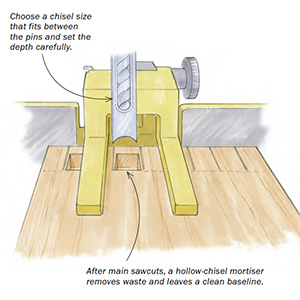

The cutting tool consists of a square hollow tube with a relief, or emptying slot, cut out of one face (sometimes two slots on opposing faces). The tool is internally flared and sharpened at one end and turned down at the other end to fit into a collet (see the Three ways to cut mortises. The author uses a large footoperated mortiser (left), a capable but expensive tool. Alternatives for smaller shops include dedicated benchtop mortisers like this Multico (below) and an attachment for a drill press (bottom). drawing at left on the facing page). Within the tube is a doublespur machine bit (with no point) that telescopes through the chisel and fits into a drill chuck. The way it works is simple: As the tool plunges into wood, the bit drills a hole and the chisel cleans out the corners by scraping the side walls, producing a square hole. Multiple plunges in line produce a rectangular mortise slot. Chisel sets come in square sizes from in. to 1 in. and in various lengths.

From Fine Woodworking #116

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Shop Fox W1826

Ridgid EB4424 Oscillating Spindle/Belt Sander

Stanley Powerlock 16-ft. tape measure

Log in or create an account to post a comment.

Sign up Log in