Cold-Molded Cradle

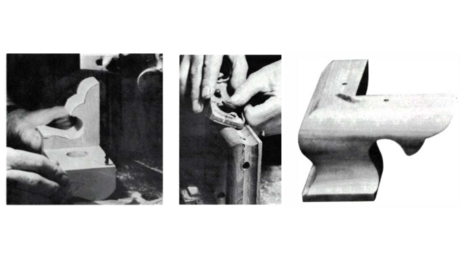

A boatbuilding method applied to furnitureSynopsis: Larry Hendricks was first inspired to apply boatbuilding methods to furniture construction when an acquaintance asked him to make an heirloom-quality cradle for a soon-to-arrive child. While discussing design, boat-like images of Wynken, Blynken and Nod, from the nursery rhyme, sailing in a wooden shoe, and the story of Moses in the bullrushes came to Hendricks mind. He’d always wanted to be a boatbuilder and this would be an excuse to experiment with the cold-molding method, a woodbending technique that relates to form laminating, but uses staples to hold strips of bent wood in place until glue cures. In this article, Hendricks details the step-by-step process with photos and instructions. This technique is then readily adaptable for all kind of curved furniture plus, of course, boats of all sizes, from canoes to schooners.

I first conceived of this cradle when I received a phone call from an acquaintance who wanted both a cradle for a soon-to-arrive child and a family heirloom that could be passed on to future generations. As we talked, I remembered the popular nursery rhyme in which Wynken, Blynken and Nod sail off in a wooden shoe, and the design popped full blown into my head. Sketching my idea on the back of an old envelope, the story of Moses in the bullrushes and the notion of launching an infant on a new life came to mind as the cradle took on its boat-like shape.

The boat idea suited my customer and me perfectly. I’ve always wanted to be a boatbuilder and the cradle project would give me an excuse to experiment with a boatbuilding method called cold-molding, a woodbending technique related to the form laminating process described in FWW #54. Cold-molding differs from form lamination in one important way: instead of bending the wood by laminating many glue-coated thin strips between two forms-a male and female-the curved shape is

made by wrapping strips of veneer around a mold, layer by layer, until the desired thickness is achieved. Staples temporarily hold each layer in place uotil the glue cures, so you don’t have to

struggle with mating two forms accurately or with a lot of clamps. With cold-molding, compound curves are easily achieved and the resulting structure is so strong that internal bracing isn’t needed. The process I’ve described here is readily adaptable for all kinds of curved furniture plus, of course, boats of all sizes, from canoes to schooners.

For the full article, download the PDF below:

From Fine Woodworking #57

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Comments

Not sure where to report this...PDF link doesn't work. Thanks!

Fixed

Log in or create an account to post a comment.

Sign up Log in