Seasoned Wood: What You Need to Know

Air-drying and kiln-drying both yield top-quality lumber

Synopsis: To wood technologist William W. Rice, it doesn’t matter whether wood’s been air-dried or kiln-dried, as long as it’s seasoned properly. He talks about wood and moisture basics and the differences between kiln-drying and air-drying. He suggests controlling temperature and humidity, if possible, indoors. He explains how to stack your wood and how drying conditions affect its color. He talks about checking moisture before bending or gluing wood and how differences in moisture affect finishing and workability. Then he addresses letting the wood acclimate to the place in which it will be used.

As a consultant and wood technologist, I’m frequently asked whether air-dried or kiln-dried wood is best for making furniture. The answer is short and simple: It doesn’t really make any difference, as long as the wood has been seasoned properly. Both methods produce good cabinet-grade material that is difficult, if not impossible, to tell apart. Properly dried wood is just that—properly dried wood.

Many furnituremakers have a preference regarding air-dried or kiln-dried lumber. Their opinions probably are a result of what kind of lumber is available to them and what they’re used to working. And it’s true there are some subtle differences between airdried and kiln-dried lumber. But the way lumber is handled during the drying process and how it is stored before use have much more to do with its overall quality.

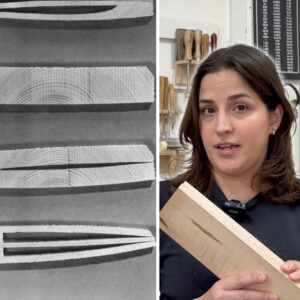

The basics of wood and moisture

Unless it’s standing dead wood, lumber is water-laden when it’s cut. Good drying, or seasoning, regulates the rate of moisture loss so that shrinkage is controlled. Checks, splits and twist occur when this process is rapid and uncontrolled.

To understand wood seasoning, you need to know a little about the terminology of drying. The amount of water in a piece of wood is expressed as a ratio of water to the weight of the wood when it’s perfectly dry. This percentage is called the wood’s moisture content (MC). A freshly cut log contains a lot of water. In some species, the MC exceeds 100%, meaning that the water trapped in a piece of wood weighs more than the wood itself.

Wood should have an MC of between 6% and 8% before it is used, unless you make green-wood furniture. Both air-drying and kiln-drying accomplish that. Even after it has dried, wood responds to surrounding temperature and humidity. Wood gives up moisture when the air is dry and absorbs moisture when it’s humid. Eventually, wood comes into balance with its environment when it is no longer absorbing or giving up any water. That’s its equilibrium moisture content (EMC). Keep in mind that all wood, whether it has been air-dried or kiln-dried, responds in the same way to changes in humidity. An accurate way to check the MC, whether wood has reached equilibrium or not, is with a moisture meter.

From Fine Woodworking #120

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Ridgid R4331 Planer

AnchorSeal Log and Lumber End-Grain Sealer

DeWalt 735X Planer

Log in or create an account to post a comment.

Sign up Log in