Stickley-Style Legs

A router bit and two jigs yield quartersawn figure on all four sides

Synopsis: Patrick Nelson explains the unique way Stickley furniture legs are designed to show figure on all four sides. His method is slightly updated, because the shaper bits used to mill the original Stickley design are not commonly available today. He uses a lock-mounted router bit to cut the legs, and he explains how to build two jigs to cut the profiles. Drawings and photos show how the jigs work. Then he uses battens and bungee cords during glue-up to prevent screw holes and weak clamping spots.

Quartersawn oak is synonymous with Craftsman furniture. The wood’s wild ray figure is both beautiful and distinctive. Unfortunately, Mother Nature saw fit to put it only on opposing faces of a board. So on a table leg, for example, the sides adjacent to a quartersawn face should be flatsawn and without figure.

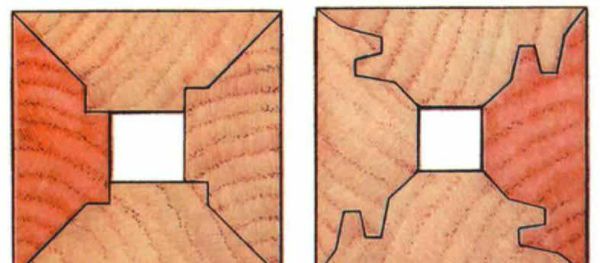

However, if you look closely at much of the furniture built by the Stickleys in the early 1900s, you’ll see what looks like a freak of nature: quartersawn figure on all four sides of square table legs (see the photo at left). This figure is the result of a unique leg design used in Stickley factories.

The Stickleys used two techniques. One was to cover the flatsawn faces with quartersawn veneer. The other technique mated four quartersawn boards with trapezoidal profiles. The base of each trapezoid was one face of the leg, and the two adjacent sides were angled at 45°. On one angled side, there was a small perpendicular notch; on the other side was a complementary tooth. Mating tooth to notch on adjacent pieces lined up the four joints perfectly.

One modern bit does the trick

The shaper bits used to mill the original Stickley design are not commonly available today, but the widely available lockmiter router bit can be used to make these Stickley-style legs. The bit is beveled at 45 °, like a large chamfer bit, with a pair of opposing teeth in the middle of the cutting surface. It cuts a profile that’s quite similar to the one used by the Stickleys. I bought my bit from Grizzly Imports. They’re also sold by a number of other router-bit manufacturers.

The lock-miter bit actually has some advantages over the shaper cutters used by the Stickleys: This bit produces a joint with a larger glue-surface area, only one is needed to cut both sides of the joint, and just one setup is required. Adjusting the lock-miter bit height and the position of the fence to get that setting is just trial-and error. You can get pretty close right from the start, though, by centering one of the teeth on the stock. And once you have the setting right, the actual routing takes just a few minutes.

From Fine Woodworking #121

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Sketchup Class

Stanley Powerlock 16-ft. tape measure

Starrett 12-in. combination square

Log in or create an account to post a comment.

Sign up Log in