Curved Table Aprons

Layers of bending plywood faced in veneer are light and strong

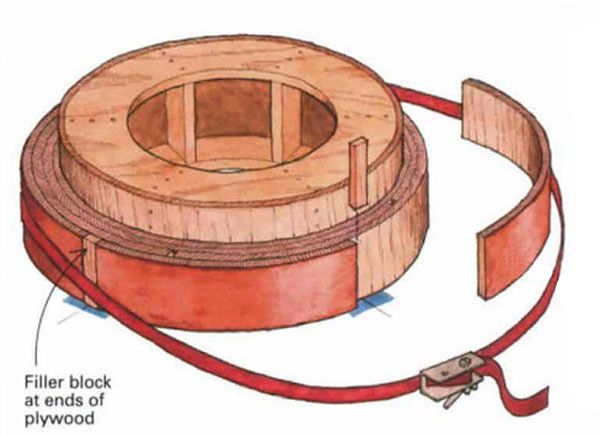

Synopsis: Bruce Peterson likes to find production methods that save time but don’t sacrifice quality. The tables he shows here have simple joinery, and he laminated layers of bending plywood capped by veneer around a circular form to make the apron. He talks about how he arrived at the design and how he built the forms – one each for the inner and outer cores. He explains how he cut and glued up the apron, how he bent the layers, and how he attached the legs and top to the apron. Detailed drawings show how he used the bending forms.

As a furniture builder, I’m always looking for production methods that save time but don’t sacrifice quality. A good example is a series of veneered tables with circular aprons that I build to sell through galleries. The joinery is simple, so I can concentrate on the details: veneer-matching, shaping, inlaying and finishing. I have a vacuum bag, which speeds up the veneer work considerably, and I use jigs to taper the legs and to cut the joinery that connects the legs to the apron. The challenge was figuring out how to make strong and stable round aprons quickly.

Initially, I considered the more traditional methods of forming a curve out of solid wood. But those methods are neither easy nor economical. Steam-bending requires equipment and set-up time. Laminating and bricklaying solid wood involve lots of cutting, fitting and clamping.

What I needed was a faster, less-expensive way to form a curved apron. I experimented with laminating strips of 3/8-in. bending plywood around a circular mold, or form. With some refinement, I could make a small table apron, ready for veneer, in just a few hours. And this construction is more stable and quite a bit lighter than a solid-wood apron.

The trick to this process is the bending plywood I use to make the circular form and the table apron (see the photo at right on the facing page). The plywood can be bent into fairly tight curves, but it will only bend along one axis. The two most common types are Wiggle Wood (also called Wacky Wood or Bendy Board) and Italian bending poplar. Wiggle Wood is available in ¼in. and 3/8in. thicknesses. Italian bending plywood is 3mm thick (just under 1/8in.). Both come in 4×8 sheets. Large lumberyards carry one or both varieties. I used -in. Wiggle Wood for my table aprons.

From Fine Woodworking #122

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Whiteside 9500 Solid Brass Router Inlay Router Bit Set

Bahco 6-Inch Card Scraper

Log in or create an account to post a comment.

Sign up Log in