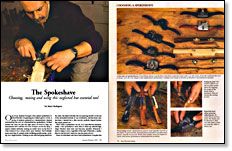

Using a Spokeshave

Choosing, tuning and using this neglected but essential tool

Synopsis: Mario Rodriguez works quickly, quietly, and effectively at shaving inside curves, cleaning up cabriole legs, shaping Windsor chair seats, and fine-tuning spindles. If his spokeshaves skip, chatter, or tear up the wood, he says, they just need a quick tune-up. Rodriguez shares the history of the spokeshave and tells how to select a set; you only need two, one flat, and one rounded. It takes practice to learn how to sharpen a U-shaped blade on a buffing wheel, and he explains the difference between wooden and metal spokeshaves. He explains and demonstrates how to tune and use one.

One of my students brought a flea market spokeshave to school last fall, complaining he couldn’t get it to work. A group of students gathered as I disassembled, cleaned and tuned up the tool. As I reassembled the spokeshave, I looked around the shop for just the right piece of wood to help me demonstrate how well the tool now worked. Across the shop, I spied a student tediously sanding an inside curve on the first of what looked to be a dozen thick, pine brackets. She’d already spent more than 15 minutes at the oscillating spindle sander, working on a single bracket. Choking on the dust and going deaf from the noise, she didn’t look like she was enjoying herself. I took one of her unsanded brackets to my workbench, and just three minutes later, I handed her a silky smooth, perfectly shaped bracket. She nearly passed out.

That’s what a spokeshave can do. As a reproduction furnituremaker, I use spokeshaves most often to clean up cabriole legs, shape Windsor chair seats and fine-tune spindles. Whenever I have to shape a curve, regardless of the style of furniture, a spokeshave is the first tool I reach for (see the photo above).

Some woodworkers who have used spokeshaves complain that they skip, chatter or just tear up the wood. A quick tune-up, the right grip and a basic technique will eliminate these problems.

The evolution of the spokeshave

The earliest spokeshaves, dating at least to the 15th century, were wooden affairs with U-shaped, friction-fitted blades. Adjustments were made by tapping the tangs of the blade with a hammer. Many shaves of this type can still be found in antique-tool shops and auctions. Because they’re so light and have such a low blade angle, these spokeshaves are a delight to use.

Over the years, the addition of threaded adjustment mechanisms improved the spokeshave. Toolmakers also began introducing spokeshaves with wear plates of boxwood (which is a very dense, tight-grained wood) and brass (see the bottom left photo on the facing page).

However, the real change came with the introduction of the metal spokeshave in 1860. The blade in a metal spokeshave is flat so that it can be sharpened easily—just like a plane blade. With a wooden spokeshave, the easiest way to sharpen its U-shaped blade is on a buffing wheel. This is a freehand operation that takes some practice.

From Fine Woodworking #122

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Veritas Wheel Marking Gauge

Suizan Japanese Pull Saw

Starrett 4" Double Square

Log in or create an account to post a comment.

Sign up Log in