Cabinet Scrapers

You'll get a smooth and flat surface, even on hard wood and curly grain

Synopsis: Monroe Robinson worked on a dining table for three months — it seated 18 people and was 13-1/2 ft. long by 5 ft. wide. The last thing he wanted was a flaw in the top. To smooth it, he had to work with a cabinet scraper. The repair took 16 hours, but there was no chipping, gouging or tearout, and he didn’t use a single sheet of sandpaper. Robinson talks about which models are still being made. The bevel angle isn’t critical; but a well-prepared blade is. He talks about how to prepare and use a No. 80 scraper and variable-angle cabinet scrapers, and he troubleshoots why the variable-edge scrapers might be working poorly. He offers tips on scraping a large surface, as he did, and about how an extended body on the scraper helps. Side information deals with modifying an antique Stanley No. 12-1/2 to be like a No. 112, which is considerably longer.

The dining table, ft. long and 5 ft. wide, could seat 18 people. After working on it for three months, the last thing I wanted was a flaw in the top. To smooth it—all 60-odd sq. ft. of Macassar-ebony that I had painstakingly resawn— I started with a handplane.

When the ebony, still rough from the bandsaw, showed signs of tearing, I turned to a cabinet scraper. It took 16 hours, but when I was done, the top was completely flat and smooth with no chipping, gouging or tearout. And no sandpaper.

A cabinet scraper is the ideal tool for smoothing and flattening any dense hardwood, especially if the grain is difficult and prone to tearout. Figured oak, ash or maple and most tropical hardwoods are all good candidates for surfacing with a cabinet scraper. A belt sander may remove wood as quickly as a cabinet scraper, but a scraper is much less likely to chew through veneer into the substrate or create ugly dips in the surface. A cabinet scraper not only smooths the wood’s surface but flattens it as well.

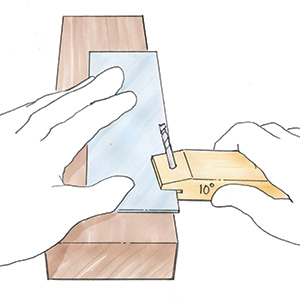

Cabinet scrapers are simply tools for holding blades at a fixed angle and depth of cut. They are pushed like Western planes, and some cabinet scrapers, like the one in the photo below, look like handplanes. Others, like the one in the photo above, look more like large spokeshaves. All hold a blade at an acute angle to the work, so a burr on the blade cuts the wood just like a hand-held scraper. But the cabinet scraper has several advantages over a hand-held scraper. Because the cabinet scraper has a sole like a plane, the amount of blade in contact with the work is limited. As a result, the cabinet scraper takes down just the high spots and skims over any low areas.

From Fine Woodworking #123

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Starrett 12-in. combination square

Veritas Micro-Adjust Wheel Marking Gauge

Stanley Powerlock 16-ft. tape measure

Log in or create an account to post a comment.

Sign up Log in