Cock Beads Dress Up a Drawer

A 17th-century detail stands the test of time

Synopsis: Cock beads and incised beads add visual interest to a range of furniture styles, from Federal to Shaker-inspired, writes Garrett Hack. He finishes building and fitting a drawer to its opening before cutting the rabbets to house the cock beads. He uses half-blind dovetails and rabbets the sides of the drawer to the base of the dovetail pins. Beads can be shaped with a number of tools, including a router, beading planes, a Stanley No. 66 beading tool, and homemade scratch beaders. He shows two ways to work your way around the drawer, and he also explains what incised beads are and how to make them. Side information discusses incised beads (eads cut into and flush with the face of the drawer). Hack uses a homemade beader with a chisel, marking knife, and a block plane. He says the trick is to take your time and work carefully — especially around corners.

In the late 17th century, English to surfaces veneered in burls and other wild-grained exotic woods. The thin veneers were vulnerable to chipping unless they were protected by molding. Drawers were especially at risk. Edges were completely exposed when the drawer was open, and simply opening and closing the drawers could damage the veneer on the drawer front. Then some innovative furnituremaker came up with the idea of attaching small, molded strips to the drawer edges. They protected the veneer and gave the drawer a distinctive border. A detail was born.

Interest in cock beading survived into the Federal period, even on surfaces that were not veneered. Cock beads were used like string inlay—to create a line around a drawer face or along a table apron.

I use cock beads in many of my designs, both around drawers and at the bottom of aprons. Cock beads and imitation cock beads, called incised beads, add visual interest to a range of furniture styles, from Federal to Shaker-inspired.

Cock beading a drawer is quite easy. There are three steps: cutting the rabbet for the bead around the drawer front; shaping and sizing the bead to fit the rabbet; and mitering and securing the beads in place.

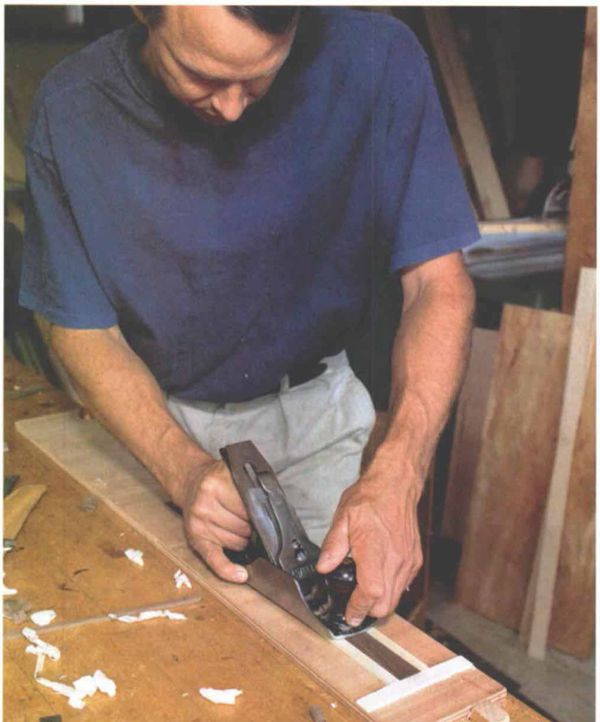

Rabbets are routed and then cleaned with a plane

I finish building and fitting a drawer to its opening before cutting the rabbets to house the cock beads. Anything more than the smallest amount of fitting done after the bead is glued in place will be noticeable. If you take a few shavings off the sides of a drawer that’s too tight, all of a sudden, the cock beads on the drawer’s sides may look thinner than the top and bottom beads.

In earlier days when dovetails were just construction joints rather than aesthetic focal points on a piece of furniture, cabinetmakers did not mind covering their dovetails with cock beads. Today, however, furnituremakers generally want their dovetails to be seen.

From Fine Woodworking #123

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Veritas Precision Square

Stanley Powerlock 16-ft. tape measure

Lie-Nielsen No. 102 Low Angle Block Plane

Log in or create an account to post a comment.

Sign up Log in