Building a Sleigh Bed

Sensuous curves and well-chosen details enhance a simple design

Synopsis: Christian Becksvoort didn’t have time to build a sleigh bed he liked, so he figured out how to capture the essence and build it efficiently – in less than 100 hours. The bed is a very simple construction. The headboard and footboard assemblies are joined to a pair of thick rails with knockdown fasteners. These assemblies are each made up of two posts into which are tenoned a turned crest rail and a flat lower rail. A single large panel floats in grooves in both posts and in the crest and lower rails. A template speeds fabrication of the posts, and he explains how he laid out and cut the mortises and sized the side rails. A detailed project plan and lots of photos illustrate his construction, and a side explanation addresses how to turn rosettes.

I’ve been building furniture full-time for 21 years and have made more than 1,000 pieces, including dozens of beds. But until recently I had never built a sleigh bed. So when a friend and long-time customer asked me to build one for her, I had some research to do. The nicest one I found was designed and built by William Turner and featured in FWW #91. To my eye, it was all a sleigh bed should be. It had classic lines, style, grace. The only problem was that it took 1,200 hours to build. My client’s budget dictated that the bed be built in less than 100 hours. So I had to capture the essence of a sleigh bed, but build it efficiently.

The design work was left to me, with just a few stipulations: The bed was to be queen size, and both headboard and footboard were to be 54 in. high. I worked out several sketches for the post profiles, finally settling on the one on p. 56. Along with twin bands of cove-and-bead molding that ring the bed and rosettes at the top of each post, this profile gave the bed the classic look I wanted.

I saved time on this bed by using flat panels for the headboard and footboard, rather than coopering a curved panel or using a tambour. Also, instead of carving the rosettes, I turned them. It took less than an hour and a half.

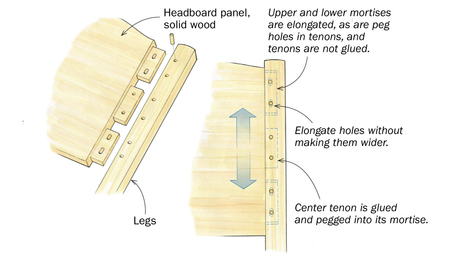

The bed is a very simple construction. The headboard and footboard assemblies are joined to a pair of thick rails with knockdown fasteners. These assemblies are each made up of two posts into which are tenoned a turned crest rail and a flat lower rail. A single large panel floats in grooves in both posts and in the crest and lower rails.

A template speeds fabrication of posts

The crest rails had to be 61½ in. long, but my lathe’s capacity is only 39 in. So I farmed them out to a local millwork shop where I used to work. While I was at the shop, I ordered eight 8-ft.-long pieces of cove-and-bead molding.

From Fine Woodworking #124

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in