Fine-Tuning a Bandsaw

Vibration and wandering cuts are signs your bandsaw needs a checkup

Synopsis: An improperly adjusted bandsaw will do everything but cut well. There’s no single saw component that causes most ills, and fixing them doesn’t involve a lot of fancy equipment. Wrenches, try squares, a file and some washers for shims are often all you need. Robert Vaughan explains diagnostics and adjusting techniques, starting with making sure the tires are smooth and crowned, then aligning the blade to the guidepost. Wheels in a twisted configuration will cause tracking problems. He includes a troubleshooting guide to help address most common bandsaw problems.

An improperly adjusted bandsaw will do everything but cut well. It may throw, break or dull blades quickly. Or it may produce cuts that wander like a drunk failing a roadside sobriety test.

I’ve performed surgery on a lot of bandsaws, and I have discovered there’s no single saw component that causes most ills. Many jumping and tracking problems can be traced directly to wornout tires. But a vibrating bandsaw may just as likely be handicapped by a beaten-up drive belt. A saw that refuses to cut squarely may be affected by a guidepost that is out of alignment, or the saw may have one of its wheels out of line.

Solving many of these problems doesn’t require a lot of fancy equipment. Basic tools such as wrenches, try squares, a file and some washers for shims are often all you need. A few diagnostics and adjusting techniques will bring out the best performance your saw has to offer. The basics include checking your tires for wear, wheel alignment, guidepost alignment and adjusting the guides and blade tension. Begin your tune-up by unplugging your machine.

Tires must be smooth and crowned

I begin a tune-up by opening the wheel housings and blasting the works with compressed air to clear out the sawdust. Then I look at the wheels and tires. If a wheel is broken or badly bent, there’s not much you can do except replace it.

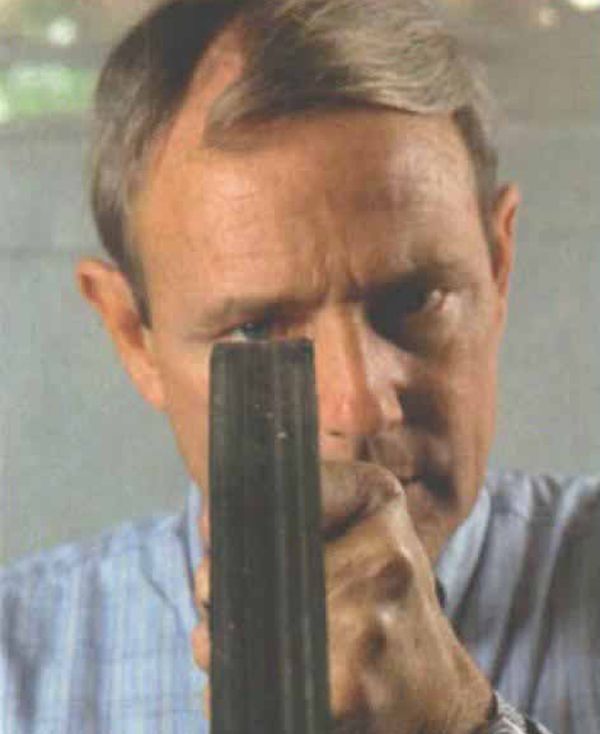

If your bandsaw tracks poorly or jumps excessively, chances are the tires are worn. The majority of bandsaw tracking and jumping problems begin and end here. Tires should be whole, not missing large chunks, and without hairline cracks. The surface should be smooth, clean and slightly crowned (see the top photo). The crown defines where the blade tracks. Blades have a tendency to wander back and forth on the surface of uncrowned tires. A crown also keeps the teeth from cutting grooves in the tire’s surface. A grooved surface will make tracking unpredictable (see the bottom photo).

If you cut a lot of resinous woods, you may have a gummy buildup on the tires, which can create a false crown. That condition can foul the blade’s tracking, allowing it to drift. You can check this by turning on the machine and letting it idle.

From Fine Woodworking #124

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Rockler Dust Right 1250 CFM

Ridgid EB4424 Oscillating Spindle/Belt Sander

Festool Cleantec CT 26 E HEPA Dust Extractor

Log in or create an account to post a comment.

Sign up Log in