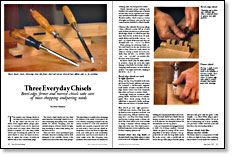

Three Everyday Chisels

Bevel-edge, firmer and mortise chisels take care of most chopping and paring needs

Synopsis: Every ragged rabbet, gloppy glue-line, and oversized tenon can be improved by the touch of a sharp chisel, writes Sven Hanson. In this article, he talks about three chisels a well-equipped shop can’t do without, and what they’re most commonly used for. Bevel-edge chisels are used in tight quarters, firmer chisels can pare tight tenons, and mortise chisels need to be strong. He discusses the anatomy of chisels and how mallets help in using them. He closes with a word on safety equipment and side information on how to angle your chisel for precision cuts.

The number one cleanup device in my shop isn’t a broom or a vacuum, as any visitor can tell you. It’s a chisel. Every ragged rabbet, gloppy glueline or oversized tenon can be improved by the touch of a sharp chisel. When fine joinery is required, it’s a sure thing chisels will be part of creating the perfect fit. You need chisels to chop out hand-cut dovetails, to square the corners of router-cut rabbets and to trim countersunk plugs.

The bench chisel family tree has three main branches: bevel-edge chisels for a variety of trimming and paring work, mortise chisels for serious chopping, and the catchall category of firmer chisels for lightduty mortising or heavy-duty paring (see the photo above).

There are other, more specialized types of chisels. But your workshop will be wellequipped if you carefully choose a few chisels from each of the three main groups. The main thing to consider when shopping for chisels is your needs. If you plan to do a lot of heavy chopping in hardwoods, the money invested in tools with reinforced handles and properly tempered steel will be well worth it. But if you use chisels infrequently or if you use them for light-duty work, you could get by with moderately priced tools. And if you need chisels to do some rough work, like chopping away at interior trim where there’s the likelihood of hitting nails, buy inexpensive chisels.

Chisels demand proper striking tools. Handles with metal striking caps or ferrules at both ends can be whacked with a hammer; unreinforced handles require a mallet. Wooden mallets, which come in a variety of weights and shapes, give you the most control and are friendly to a chisel’s handle.

Choose the chisels for your shop

I have collected a pretty full set of each style of chisel, but they’re not all necessary. Bevel-edge chisels, so called because they have three bevels on their faces, fit easily inside dadoes and dovetails. I use my in. and -in. chisels all the time and chop out dovetails with -in., -in. or -in. chisels.

When picking out mortising chisels, select ones based on the size mortises you plan to chop. These are costly; there’s no value in owning a whole set if you routinely chop out only -in. mortises. I find -in., -in., -in. and -in. mortise chisels serve most of my needs. My firmer chisels play the utility infielder position, doing the work that might damage a thin-blade bevel-edge chisel or chopping small mortises on more delicate projects. You might need a few, ranging in size from in. to in.

From Fine Woodworking #124

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Veritas Wheel Marking Gauge

Starrett 12-in. combination square

Olfa Knife

Log in or create an account to post a comment.

Sign up Log in