Fitting a Drawer

A traditional British approach to the classic piston fit

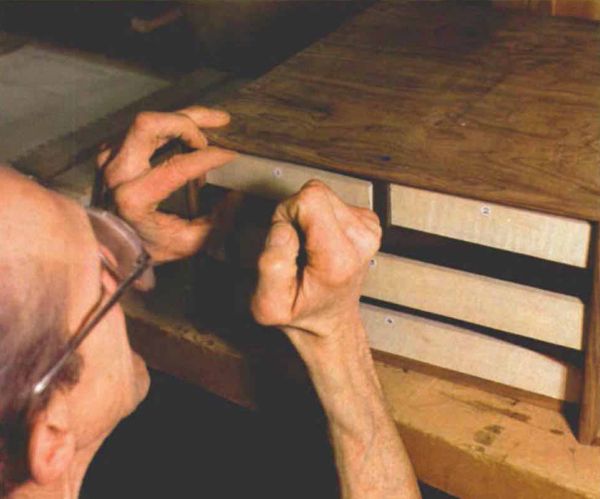

Synopsis: Renowned English designer and woodworker Alan Peters discusses how fine furniture requires an approach that substitutes craftsmanship for manufactured precision. The technique he describes here (and uses in his shop) involves three successive levels of fitting. The first is of the individual drawer parts, then the assembled drawer without its bottom, and then with the bottom installed. Well-built drawers start with stable wood, and he explains how to select and prepare it. Then he fits drawer pieces individually and precisely. He explains how to fit the drawer box and trim it to fit. All that remains then is to determine the position of the front, using the drawer stop. Peters advises proceeding cautiously. Detailed photographs follow each step in his drawer construction.

My wife, Laura, doesn’t understand why I make such a fuss about drawer fitting. The drawers in our kitchen cabinets slide on plastic runners, and she says they work better than the drawers in any of my furniture. I can’t argue with that—those nylon rollers do their job well. But plastic slides don’t belong on dovetailed drawers. Fine furniture requires another solution, an approach that substitutes craftsmanship for the manufactured precision of drawer slides.

The technique we use in my workshop involves three successive levels of fitting. The first is of the individual drawer parts, then the assembled drawer without its bottom and, finally, the drawer with its bottom installed. The result is a drawer that fits so well that it’s slowed by a cushion of air as you push it in. And when you pull out the drawer, any other drawers in the case are gently pulled back into the nearly airtight case. It takes time to achieve this piston fit, but the results speak for themselves. Other furnituremakers may pride themselves on their dovetails or some other joinery, but for me, a finely fitted drawer is the benchmark of a craftsman’s skill.

Well-built drawers start with stable wood

Drawer sides should only be made of top quality, mild-grained and, preferably, quartersawn stock. What you are looking for is wood that will remain straight, move very little with shifts in humidity and plane easily and cleanly. At the top of my list is Honduras mahogany. Most of my drawer sides are made of material salvaged from old, factory-made mahogany furniture. Because of its age, the wood is about as stable as it’s ever going to be. After mahogany, quartersawn oak is my choice for drawer sides.

I make my choice depending on the wood used for the drawer fronts, always aiming for a contrast in color. I like mahogany with lighter colored drawer fronts, such as ash or sycamore, and oak sides when the drawer fronts are made of darker woods, such as walnut or rosewood. From time to time, I use other woods, such as teak, because it wears so well, and rippled (curly) sycamore on special cabinets or desks, where the visual quality of the drawer sides is very important.

Fit the drawer pieces individually and precisely

Regardless of how much care you put into making and fitting the drawer, it will not fit well if the opening in the case is not consistent front to back and top to bottom. Check the openings, and true them with a shoulder plane if necessary. Make sure, .above all, that the case doesn’t taper in from front to back. Once the case is trued up, sand the inside, and polish it with a good-quality paste wax.

From Fine Woodworking #125

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Bessey K-Body Parallel-Jaw Clamp

Bessey EKH Trigger Clamps

Stanley Powerlock 16-ft. tape measure

Log in or create an account to post a comment.

Sign up Log in