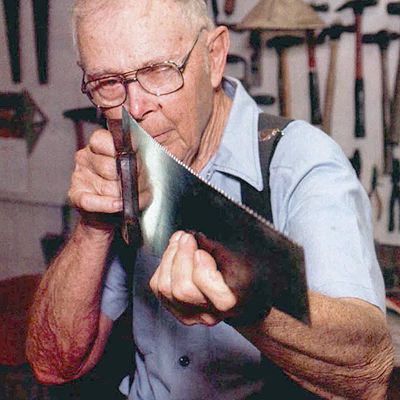

Synopsis: Former Seabee Fred Wilder explains how to sharpen a handsaw – what tools you need, how to straighten, joint, and set the saw, and how to file the teeth to sharp points. He covers subjects such as holding the file and reducing the flats to even points. Side explanations delve into how to reshape jointed teeth before setting and how to file angles on crosscut and rip saws.

Someone asked, “Will a sewing needle slide down the tooth edge of a carpenter’s handsaw?” It was the end of another day on Attu Island, a barren, wind-swept speck of land at the end of the Aleutian chain. We were a bunch of homesick carpenter Seabees sitting around the stove in a Quonset hut, waiting for lights out. The question hung in the air, and then there was laughter. There wasn’t much to do at night, but that last question really scraped the bottom of the barrel for a conversation topic.

Still, we were curious. One of the other carpenters retrieved a crosscut saw from his tool kit. We gathered around while he placed a needle on the teeth. When he tilted the saw, the needle ran down the edge like a streak of quicksilver. The question had been answered. But I knew it didn’t mean that the saw was sharp, just that the blade was straight, and the teeth had been set and filed evenly.

Only the very points of the teeth do any cutting. They could be dull as ditch water and the needle would still slide just as fast because it doesn’t ride on the points of the teeth, but between them. Even so, you could say that needle sliding does show something. If the needle slides well, you know that you’re at least halfway to making a saw ready for the work it was designed to do.

The tools you’ll need for sharpening

A jointer, a file, a saw clamp, a saw set, a hammer with a convex face and an adjustable light are the main tools you’ll need to sharpen your saw. You can make a perfectly good jointer by attaching an old 6-in. mill file to a block of wood. The file that I use to sharpen sawteeth is a 7-in., double extra-slim taper. It works fine for all teeth sizes. You can either buy an old saw clamp at a flea market or you can make one. You just need some way to put even clamping pressure along the blade.

A saw set bends the teeth so that they cut a kerf wider than the sawblade. My choice of saw sets is a Taintor. It has a thin washer that can be put under the set anvil to change the amount of tooth that is bent over. Saw sets with a fixed anvil height may set large teeth at the right height but will set small teeth too low. The Taintor also has a second plunger that clamps to the saw before the set plunger sets the tooth. This feature reduces the chances for error in holding the saw set on the tooth.

From Fine Woodworking #125

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Lie-Nielsen No. 102 Low Angle Block Plane

Stanley Powerlock 16-ft. tape measure

Veritas Micro-Adjust Wheel Marking Gauge

Log in or create an account to post a comment.

Sign up Log in