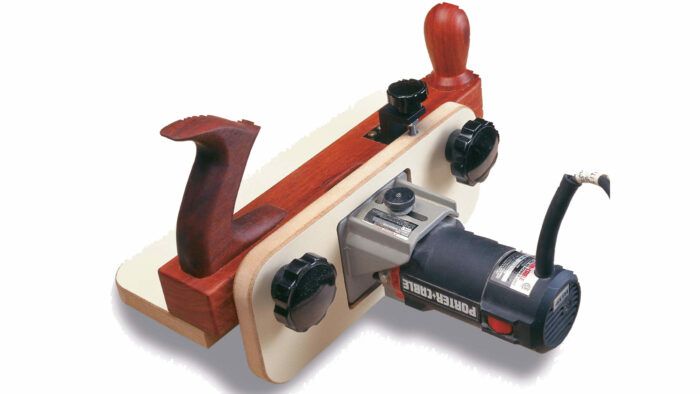

Shopmade trimmer

Simple carriage steadies trim router to flush-cut plywood edge-bands

Synopsis: Jim Siulinski, an applications engineer and woodworker, was looking for a way to trim off solid-wood edge-banding from cabinets. His solution was to make a carriage for a trim router with an extended base and fence and handles like those on a handplane. It works much like a handplane, and he’s found few obstacles to a clean cut. A large detailed drawing shows how he built the carriage and how he adjusts the depth of cut.

Every time I use sheet goods to make cabinets, I’m faced with the job of banding the exposed edges. I’m turned off by glued veneer tape because I worry that it will eventually peel away or chip off. It also has that department-store furniture look. I prefer a solid wood edge-band, which is more durable and more attractive.

Applying and trimming solid-wood edge-banding, though, can be difficult and time-consuming. After applying an oversized strip to the edge, you have to trim it flush with the face of the panel. I find it difficult to balance a router or laminate trimmer on a panel edge, and I immensely dislike sanding out the inevitable snipe and chatter marks from router wobble and bearing hops. I looked for a way to improve the process.

The solution is a stable carriage for the trim router

My solution was to make a carriage for a trim router with an extended base and fence and handles like those on a handplane. The trim router is mounted in the fence and attached to the base at 90°. The base rides on the face of the panel, and the fence rides along the edge. The 15-in. by 5-in. base significantly increases the surface area of the tool. It’s stable and wobble-free. An adjusting knob (see the center photo on the facing page) set into the top of the plane body allows precise alignment of the trimming bit with the bottom of the base for a perfectly flush cut.

I scrounged most of the materials from a junk pile at my workplace and from a friend’s woodshop. I used melamine with a medium-density fiberboard (MDF) core for the base and fence because it’s stable, durable and slides well over the work. The wood in the plane body is jarrah, though any stable hardwood will do. The only uncommon part is a scrap of anodizedaluminum angle bar I used for a bracket to house the adjusting knob. If I hadn’t found the angle bar, I probably would have made some kind of bracket out of wood. Like many shopmade jigs, this one is fast, easy and inexpensive to build. The whole jig took about four to five hours, start to finish.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Fein Turbo II HEPA Wet/Dry Dust Extractor

Bosch 12V Trim Router

Hedgehog featherboards

Log in or create an account to post a comment.

Sign up Log in