Synopsis: A joiner’s bench is long and narrow with a vise along the side and at one end. Chair makers frequently work on a low platform called a framing bench. All good benches share features you will want to include in any bench you are making or acquiring, says Michael Dunbar. It must be sturdy; it should be heavy. It shouldn’t move around, and it should be wide enough to handle the jobs you normally do. The height is possibly the most critical dimension, and the most personal. And bear in mind that it’s easy to raise the height but harder to lower it.

It is almost impossible to work wood without a workbench. It ranks as one of the most important fixtures in a shop. In fact, the more extensive your woodworking experience the more likely you are to have more than one bench. I have always had at least three benches in my chair-making school’s shop—large and small joiner’s benches and an assembly bench.

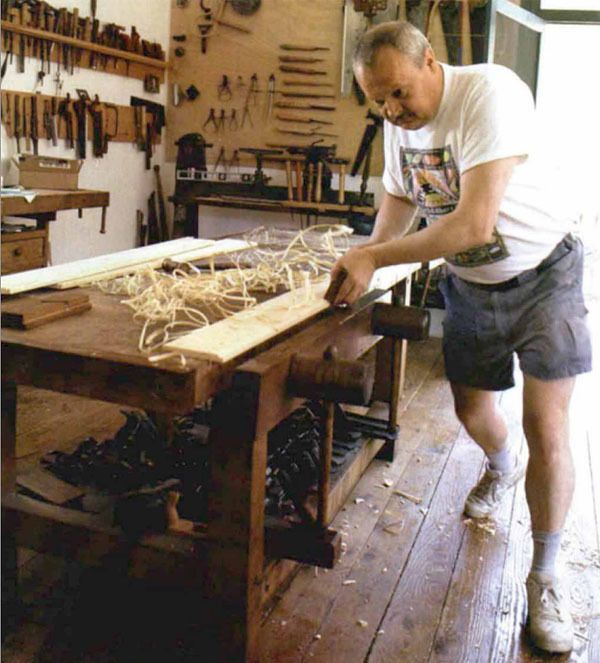

Different types of woodworkers traditionally have had different styles of benches that vary according to the needs of their craft. For example, a joiner’s bench is long and narrow with a vise along the side (known as a side vise) and a vise at one end (known as a tail vise). Chair makers frequently work on a low platform called a framing bench because chair assembly is called framing. All good benches share features you will want to include in any bench you are making or acquiring.

A bench must be sturdy. You frequently place a lot of weight on it. Woodworking, especially with hand tools, creates a lot of force. A bench that wobbles or racks under these forces is frustrating to work on because you waste a lot of energy moving the benchtop rather than working wood. Also, this type of movement is not good for the bench’s joints. They wear more quickly, and you may need to replace the bench down the road. All the benches in my shop have 4×4 legs, and the stretchers are joined with 2-in.-deep mortiseand-tenon joints. The top is secured to 2×6 cleats that are mortised to sit on tenons cut into the top of the legs. We have reinforced all the multiple person benches with cross bracing—both end to end and side to side.

A bench should also be heavy. The forces exerted upon a bench can not only rack it but also make it slide around the shop. Chasing your bench while trying to work wood is very frustrating. A heavy bench is more likely to stay put. A thick top is one way to create weight. The top of my large joiner’s bench (see the photo at left) is in.-thick beech, and all of our multiple-person benches (see the photo below) require four people to lift them safely. Storing some of your tools under the bench is another good way to add weight. I store my working handplanes, about 20 of them, on a shelf that spans the side stretchers.

From Fine Woodworking #132

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in