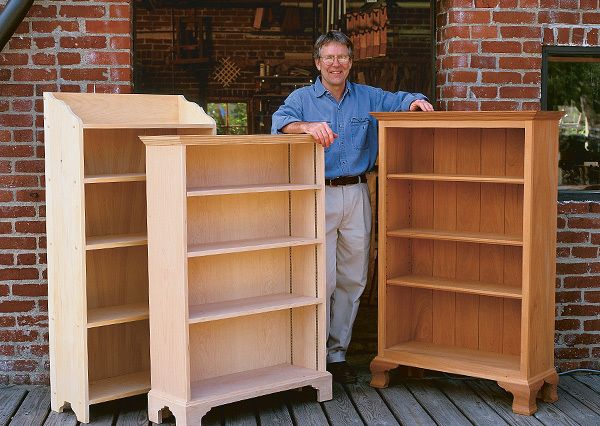

A Choice of Three Bookcases

Spend a day, a weekend or a week

Synopsis: Philip C. Lowe shows how to make three bookcases of varying complexity; which to build merely depends on time, budget, and circumstance. If you need one in a hurry, you can knock together a sturdy bookcase with premilled pine using simple dado construction. If you want something more substantial but don’t have the time or money for a solid piece, you can make a bookcase from hardwood plywood with solid wood facings. Last, Lowe shows how to make one with adjustable shelves, dovetail joinery, a face frame and curvaceous ogee bracket feet. Project plans for each version give dimensions and show construction details.

When customers arrive at my shop inquiring about having a piece of furniture made, it’s part of my job to ascertain what quality of furniture they’re looking for and to translate their desires into a dollar amount that will equal the time and materials needed to complete the piece. We all know that more time spent equals more dollars. The quicker the joinery and construction and the cheaper the materials, the less expensive the piece, and vice versa. The woodworker working in his or her home shop faces this same dilemma. Regardless of your skill level, you must decide how much time and materials are worth putting into a piece.

Imagine three scenarios. In scenario one, your floors are piled high with books, you need a handful of bookcases, and you need them in a hurry. It’s pretty hard to justify building bookcases that are going to take two weeks a piece to complete. But in a day, you can knock together a sturdy bookcase with premilled pine from the lumberyard and simple dado construction.

In scenario two, you want something more substantial than a pine case, but you don’t have the time or the money for a solid hardwood piece. In this instance, a bookcase made from hardwood plywood with solid wood facings is the ticket.

In scenario three, you have only a few books to house, no time constraints, and a pile of mahogany left over from another project. In this instance, it makes sense to build a fine, hardwood bookcase with adjustable shelves, dovetail joinery, a face frame and curvaceous ogee bracket feet.

I’ll show you how to make all three bookcases, and I’ll leave it up to you to decide which case is the right one for your time, budget and circumstance.

A quick case

If you have a tablesaw with a dado blade, a quick bookcase is as close as your local lumberyard and a day’s work. At the yard, purchase 1-in. by 12-in. D select pine, which is the most expensive but has the fewest knots. Make sure the boards are relatively free of cup, bow, twist and crook and that the thickness of the boards is consistent. When you mill the boards back at the shop, cut the shelf pieces in.

From Fine Woodworking #133

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Dividers

Blackwing Pencils

Drafting Tools

Comments

Hello, for bookcase #3 (the most complex of the three) how do you attach the base to the carcase? I’m thinking of using countersunk wood screws drilled from the bottom through the base frame, filler pieces, and into the bottom shelf, taking care not to poke through the bottom shelf. The screws in the side and rear may need to be elongated to account for seasonal wood movement.

Alternatively, or additionally, maybe there is some way to screw from the bottom into the side pieces, although I’m hesitant to do so because the side has the dovetail slot so close to the bottom and I wouldn’t want to weaken it.

Any other thoughts?

Also, what size is the blank for the ogee feet? Looks like 8/4 thick by maybe 6” wide?

Thank you.

UPDATE: there is a FWW video series for bookcases that are almost the same as this, but with plywood not hardwood. You can find them by searching for "One Bookcase, Two Bases" in the videos section.

Log in or create an account to post a comment.

Sign up Log in