Soften Hard Edges with a Side Bead

Use a beading tool, a plane or a router to shape this delicate detail

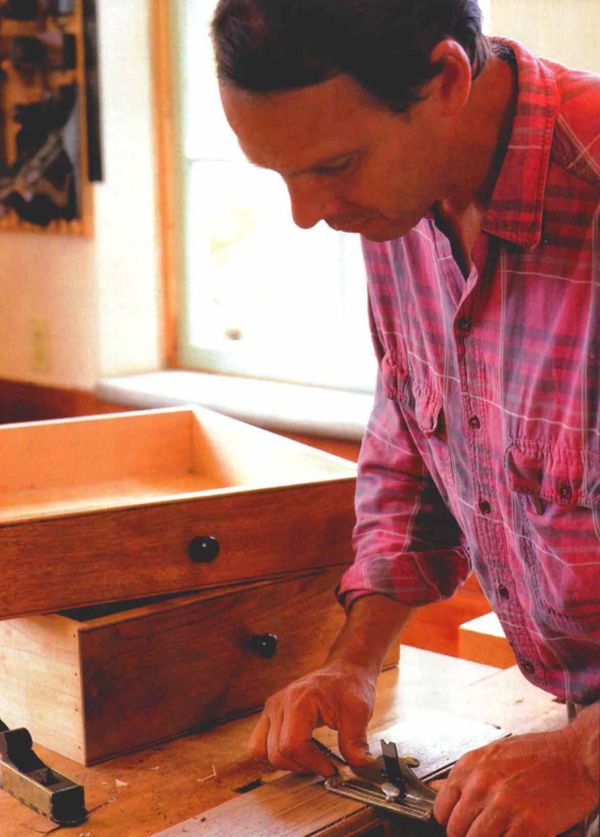

Synopsis: Outlined by a flat-bottomed groove called a quirk, a bead softens an edge, gives it definition and draws your eye along; it can hide the gaps around drawers and doors or the joints between tongue-and-groove boards. In this article, Garrett Hack explains how to cut beads three ways – with a beading tool or scratch stock, with a beading plane, and with a router. He explains when to use which tool and how to get the best results with each. He says homemade scratch stock offers more control and versatility than manufactured beading tools. Beading tools go easy around curves and cut any size of bead. Beading planes do a smooth job and cut quickly; for straight runs, they’re superior. Routers cut consistent and handsome beads as long as you can find a bit the right size and are willing to take the time to set up. Hack also explains several uses for a simple side bead. Side information explains how to make a scratch stock to the profile of your choice.

Shakers taught me about beads, the semicircular moldings they ran along the edges of everything from peg rails to door rails. Forbidden superfluous ornament, the Shakers used beads for their practicality, rounding an edge to hide wear. Outlined by a flat-bottomed groove called a quirk, a bead softens an edge, gives it definition and draws your eye along; it can hide the necessary gaps around drawers and doors or the joint between tongue-and-groove boards. Both utilitarian and beautiful, beads are quite easily added to your repertoire.

I cut beads, properly known as side beads, any of three ways: with a Stanley No. 66 beading tool or shopmade scratch stock, with a beading plane or with a router. The method I choose depends on which tool will work best for the least effort, how many feet of bead I need and the size of the bead. With a router or beading plane, I have fewer size options than with a beading tool or scratch stock, for which I can make any size cutter. A router and plane cut the most consistent beads, especially for straight runs, but a beading tool or shopmade scratch stock works best in difficult woods and can follow nearly any curve. Because I usually have just a few yards of bead to cut and prefer to work with hand tools, I most often use a scratch stock or plane. Both tools cut a bead with a hint of handmade irregularity and a fine quirk, more appealing to me than the consistent profiles cut by a machine.

Beading tools go easy around curves

The Stanley No. 66 beading tool (no longer made) and its derivative, the bronze beading tool from Lie-Nielsen, are the most common of several manufactured versions of the shopmade scratch stock (see the left photo below). All manufactured beading tools and shopmade scratch stocks work with a high angle scraping action—different from the true cutting action of a beading plane—and although they don’t cut very quickly, beading tools and scratch stocks will cut any size bead, with or against the grain, even in the most difficult woods. The Stanley No. 66 beading tool, with which I am most familiar, has a flat sole, an adjustable fence and a single cutter, which can be securely clamped into place. All manufactured beading tools come with a number of cutter profiles, as did the Stanley No. 66.

From Fine Woodworking #134

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Dubuque Clamp Works Bar Clamps - 4 pack

Stanley Powerlock 16-ft. tape measure

Festool DF 500 Q-Set Domino Joiner

Log in or create an account to post a comment.

Sign up Log in