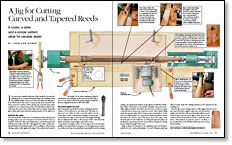

A Jig for Cutting Curved and Tapered Reeds

A router, a lathe and a simple pattern allow for variable depth

Synopsis: John M. Van Buren, a retired neurosurgeon, developed a way to cut reeds on a turned and tapered leg so that the variable depth of the reed can be adjusted with precision. He uses a lathe and two simple shopmade jigs: a horizontal router sled and a pattern made of ¼-in. plywood. He explains and shows how to make and use them in this succinct article. The pattern guides the sled in his setup. One of his tips is to cut “backwards,” moving the sled right to left, so that the bit rotation does not lift the bit and the sled off the table.

I’ve never been satisfied with any of the methods I’ve seen for cutting reeds on a turned and tapered leg. The problem is that the variable depth of the reed cannot be adjusted with precision. Obviously, for the reed to stay properly proportioned in the lower, narrower sections of the turning, the router bit must make a shallower cut so that the size of the reed diminishes with the size of the leg. This can be done with a lathe and two simple shopmade jigs: a horizontal router sled and a pattern made of 1⁄4-in. plywood.

A sled for the router

The sled holds the router bit in a horizontal position and has two bearing surfaces cut out of one piece of wood screwed to the vertical face of the sled. The top bearing surface—just below and even with the outer edge of the bit—rides against the surface of the turning and limits the maximum depth of the reeding cut. The bottom bearing surface rides against the edge of the pattern and controls the depth of cut when maximum depth is not desired—for example, at the narrow end of the leg. I use a 3⁄16-in. radius (#10.24.01) point-cutting roundover bit from Highland Hardware.

The pattern guides the sled

After turning the leg blanks but before cutting the pattern, clamp or bolt a jig base to the lathe bed. The base is a piece of 3⁄4-in. plywood with a smooth surface for the router sled to ride on and broad enough to hold the pattern and the sled. Mine is 16 in. by 42 in. The height of the jig base is adjusted with shims so that the tip of the router bit in the sled is exactly the same height as the lathe centers.

The pattern is simply a piece of 1⁄4-in. plywood cut in the same profile as the turned leg. To prepare it, set the leg between centers on a lathe, and drop a perpendicular repeatedly from the turning (using a try square) and mark it on the plywood. This line mimics the outline of the piece to be reeded.

From Fine Woodworking #138

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Hedgehog featherboards

Bessey EKH Trigger Clamps

Starrett 12-in. combination square

Log in or create an account to post a comment.

Sign up Log in