Metalworking Skills Make You a Better Woodworker

Tips on grinding, shaping and drilling metal

Synopsis: A good woodworker is often something of a metalworker, too. Lon Schleining shows how to use, adapt, modify or make tools so you’re less dependent on what’s available in catalogs. This short article begins with grinding and shaping and includes information on making a custom scraper, drilling cast iron, and tapping threads.

Like it or not, a good woodworker has to be something of a metalworker, too. The majority of woodworking tools are, after all, made of metal. The more understanding a woodworker has about working with metal, the easier it will be to tune, adapt and even make tools, all practices common to generations of woodworkers.

As a kid my first job was working in Ole Olson’s automotive machine shop, in Seal Beach, Calif. One thing I learned was to use the right tool for the job. But he also taught me that if you didn’t have the right tool, you could just make or modify one.

Recently, I showed a class how to slim down a chisel on a bench grinder so that we could cut some very small dovetails—so small that even a -in. chisel was too wide. In a jiffy, being careful to keep the chisel cool, we were able to modify the tool to fit this special application.

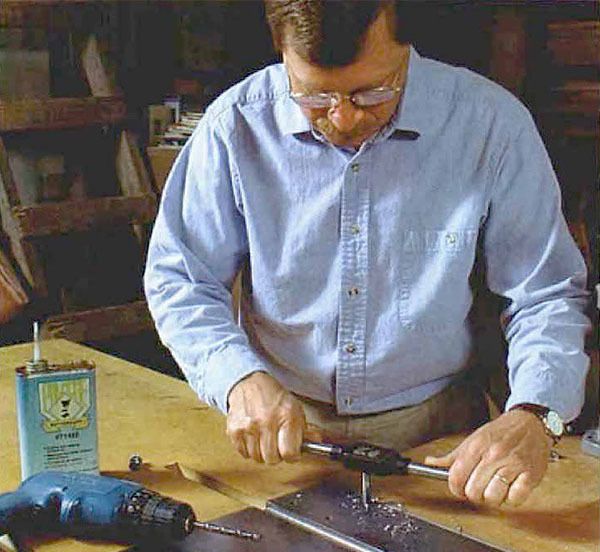

My metalworking capability advances my woodworking by opening new ways to use, adapt and make the tooling I need for woodworking. Instead of being stuck with what is available in catalogs, it has become natural to modify hardware, tools and machines, use metal in jigs, even make tools from scratch. When I look at my collection of woodworking machines and tools, I see wrenches with one end cut off to fit into a confined space, saw tables with holes drilled and tapped for accessories, scrapers cut to fit molding contours and an assortment of odd-looking but invaluable jigs and gizmos.

Many woodworkers steer clear of metalworking, remembering when they turned an expensive chisel blue with a bench grinder. But there’s nothing to fear about cutting, grinding, filing, drilling and tapping metal once you understand a few rules of thumb and invest in a few tools. If you are truly ambitious, you might even try making your own hardware, to make your furniture unique.

Grinding and shaping

As most of us have found out the hard way, it isn’t difficult to ruin a chisel on a bench grinder. But it isn’t hard to avoid ruining it, either. The important thing to remember when grinding any sort of metal is to keep it cool.

If the metal ever gets hot enough to change color, it will change the temper of the tool. If, however, you keep the tool cool enough to hold in your bare hand, you can grind all you like, modify the shape to suit the task or simply renew the bevel.

From Fine Woodworking #151

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in