Tune Up Your Router

Maintenance tips for height-adjustment mechanisms, collets and brushes

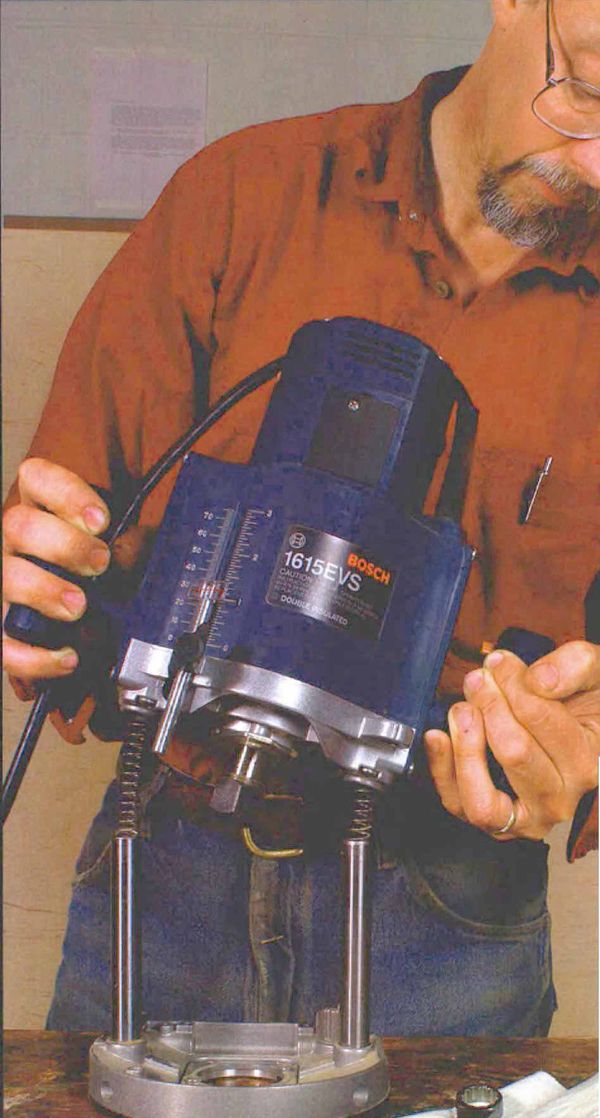

Synopsis: John White of Fine Woodworking explains how to get finicky routers into shape without spending much time or money. He shows how to fix height-adjustment issues, including a failure to lock into place; how to fix the collet if it fails to grip the bit properly, causing it to slip; and how to replace worn brushes, which prevent the motor from starting or cause it to cut out under load. White explains how to address these issues on multiple styles of routers using tools you have lying around the shop.

In most shops a router gets plenty of hard work, so it’s not surprising that an occasional problem can show up. But just because your router has been acting finicky doesn’t necessarily mean it’s time to replace it. You can often get it back into tip-top shape if you know where the problems are likely to be hiding. And chances are, the fix won’t cost you much time or money.

As manager of the Fine Woodworking shop, I get to see quite a few routers. The problems that most of them have had can be distilled into one of three categories.

The main problem I see is related to the height-adjustment mechanism. Over time it may become difficult to adjust. Or it does not lock properly, causing the motor to creep out of position.

Second on my list of common problems has to do with the collet. Sometimes it won’t grip the shank of the bit tightly enough, causing the bit to slip.

Worn brushes are the third most common problem. When brushes have worn too much, the motor might not start. If the motor does manage to run, it can unexpectedly cut out under load.

Height-adjustment problems

It’s not unusual for the height-adjustment mechanism to stick or bind, especially on a plunge router. When that happens, it’s difficult to make precise adjustments. When the height adjustment is not working quite right, the first thing to do is check the sliding components and the lock mechanism. A buildup of grime prevents parts from sliding or meshing properly. And parts that aren’t properly lubricated suffer the same problem. The fix here is simple enough. It’s just a matter of cleaning and lubricating the parts.

Unfortunately, some routers have a complex lock or height adjustment mechanism that makes disassembly difficult. In this case, first try cleaning and lubing without taking apart the router. Disassemble the machine only if you can’t get it to free up.

On a plunge router, first remove the springs from the base unit. Then use a penetrating oil, such as WD-40, and a paper towel or rag wrapped around a rod (a wood dowel works fine) to clean out the holes that accept the two guideposts. Then clean all of the old grease off the springs and wipe down the guideposts.

Use a paper towel or a rag wetted with WD-40 to get into the threads, grooves, gear tracks and other nooks and crannies of the lock and depth controls of your machine. An old toothbrush also comes in handy here.

From Fine Woodworking #152

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Milwaukee M12 23-Gauge Cordless Pin Nailer

Stanley Powerlock 16-ft. tape measure

Bosch 12V Trim Router

Log in or create an account to post a comment.

Sign up Log in