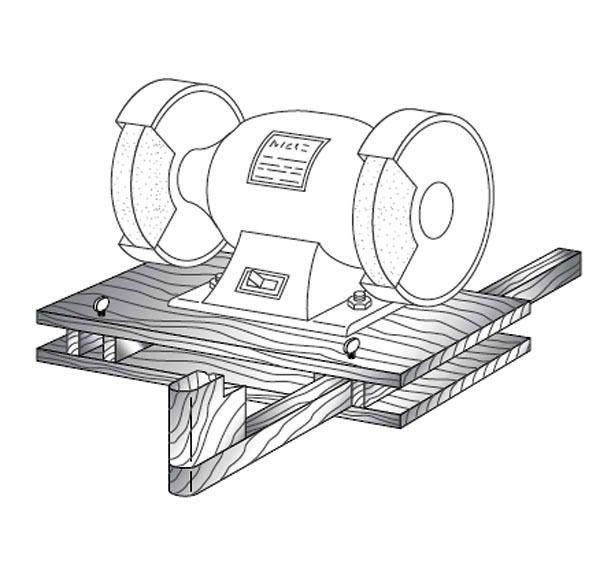

King Heiple's Shop-Built Jig

Build your own sharpening jig with these plans by Fine Woodworking author King Heiple

Creating a fingernail grind on your spindle gouge by eye is possible but difficult, even for a seasoned turner. Oneway, Sorby and Tormek all make jigs to simplify the task, but more than one woodworker has hesitated at their prices and concluded that they could make a workable sharpening jig themselves. This shop-built jig was created by King Heiple, a retired surgeon, amateur woodworker, and Fine Woodworking author.

Open or download the 1-page PDF file below for the plans to make the sharpening jig. The only metal parts in the jig are two thumbscrews and their accompanying nuts and a 1/4-in. by 6-in. metal rod that connects the pocket jig to the V socket in the adjustable-length arm. The jig can be used with 6-in. or 7-in. grinding wheels, but an 8-in. grinder gives less of a hollow grind as well as lasting two or three times as long.

Ernie Conover is a turner and teacher in Parkman, Ohio. His article “Learn to Turn Spindles” appears in the May/June 2002 issue of Fine Woodworking (#156).

Drawing: Mario Ferro

From The Lathe Book, p. 97

Log in or create an account to post a comment.

Sign up Log in