Steel Wool vs. Abrasive Pads

Even with the advent of synthetics, there is still a place for old-fashioned steel wool

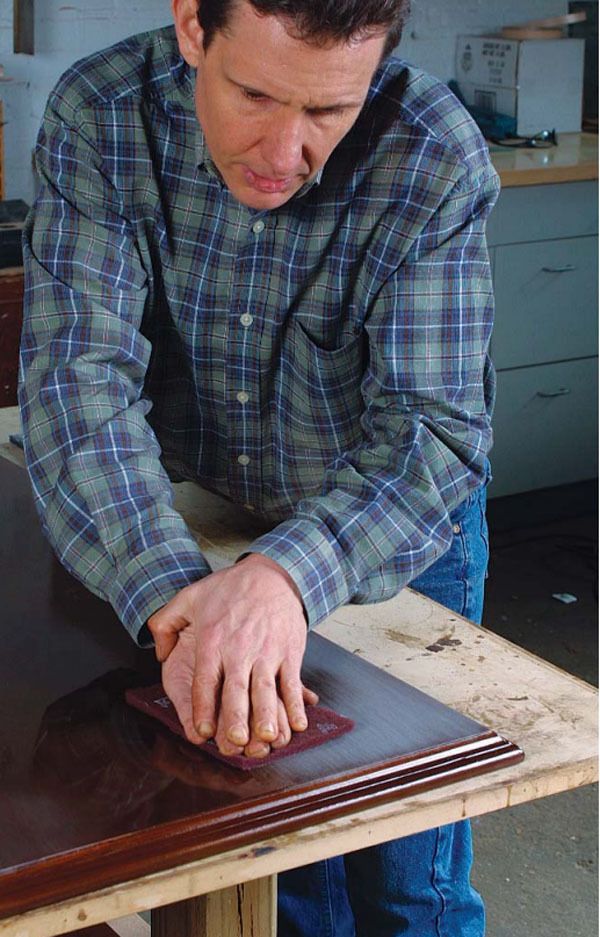

Synopsis: Jeff Jewitt, a furniture finisher and restorer, does detective work to determine whether steel wool or abrasive pads products work best for the various steps of the finishing process. Photos from an optical microscope reveal the scratch patterns left by each product. He goes on to explain where and how to use the two products, such as polishing and smoothing finishes.

I had always wondered why one grade of steel wool worked better than another, and why good steel wool seemed to produce a superior-looking surface on a clear finish than a comparable synthetic abrasive pad. Writing this article spurred me to do some real detective work.

With the assistance of Case Western Reserve University in Cleveland, Ohio, I looked at the various grades of steel wool and abrasive pads under an optical microscope. I then rubbed a clear acrylic sheet with 0000 Liberon-brand steel wool and another sheet with a gray Mirlon abrasive pad made by Mirka. The products have roughly similar abrasive powers. I then looked at the scratch pattern using a scanning-electron microscope.

The acrylic samples, coated with a thin layer of palladium to make them electrically conductive, were placed in an ultrahigh vacuum. Electromagnets then bent an electron beam, which produced an image on the screen.

I’ve been finishing and refinishing wood for going on 25 years, and of all the tools I have used consistently in that time, steel wool in one form or another has to rank among the most useful. My dad showed me how to use the stuff, and when I asked him how it was made I remember him saying, “It comes from metal sheep, silly.” Since that first time, I’ve used it for removing, polishing and cleaning finishes, sanding between coats of finish, and once I even experimented with it for applying finishes (with disastrous results).

The major change in this field has been the advent of synthetic steel wool, also known as nonwoven abrasive pads. This product has replaced steel wool for some applications, such as rubbing finishes between coats and stripping paint, and with abrasive pads constantly improving, they may continue to encroach on the uses for steel wool. But for rubbing out the final coat of clear finishes, applying waxes and cleaning old furniture finishes, nothing beats steel wool. Abrasive pads and steel wool differ greatly in quality, so let’s start by seeing how both are made and learning how to sort out the (metal) sheep from the goats. Then I’ll tell you which products are best for which tasks and how to use them.

From Fine Woodworking #159

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Veritas Wheel Marking Gauge

Festool Rotex FEQ-Plus Random Orbital Sander

Log in or create an account to post a comment.

Sign up Log in