Fight Backlash

Taking the slip out of machine adjusters makes for more accurate work

Synopsis:Backlash is a common problem on old or worn machines. George Walker shows techniques for reducing backlash and understanding it so you can achieve more precise results. He gives exact directions for cleaning, lubricating, and making corrections to machines as simple as a block plane and as large-scale as a tablesaw, among others.

When I served in a traditional machinist apprenticeship nearly 30 years ago, apprentices were expected to pay their dues, which meant running old, worn-out machines and completing jobs the more experienced journeymen didn’t want to fiddle with. I manned an ancient, dilapidated lathe that had spent its better years in Brazil. One journeyman, the cigar-puffing Dom, took me under his wing. He could run rings around me on a lathe, simultaneously whipping up sardine and cheese concoctions for both of us. Dom enjoyed watching me struggle with that old machine, occasionally offering strings of Portuguese curse words that he thought the lathe might remember. I never developed a fondness for sardines, but I did learn solid fundamentals. One of them was how to overcome backlash, a common problem that occurs in machine and woodworking shops alike. You may have a jointer, a tablesaw, a planer or a handplane that has a temperamental streak, that occasionally requires a little voodoo or that is just plain evil. Backlash may be the root of the problem.

Backlash is a necessary evil

Backlash is defined simply as the play between moving parts, such as gears or threads, and is most noticeable when changing directions. Although backlash is usually associated with old or worn machines, it’s actually a necessary part of any machine design. Without the play, or clearance, between moving parts, mechanisms would seize up, shafts wouldn’t turn, tables would not tilt or adjust. Backlash becomes a problem when that play is excessive—typically resulting from loose-fitting threads, gears or other mechanical connections—and often shows up as slop in adjustment mechanisms like the crank handles on a tablesaw.

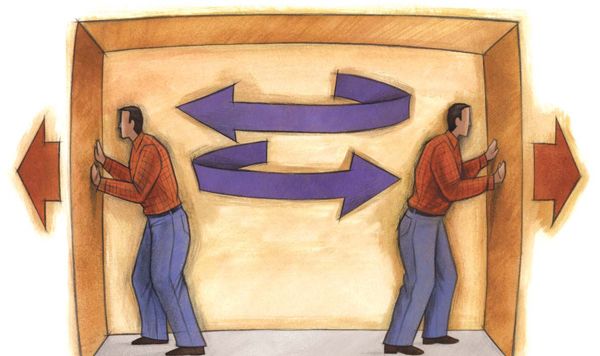

To illustrate backlash, imagine a man inside a large, overturned box. If the man wants to move the box to the right, he must walk to his right and push on that side. If he wants to push left, he must Drawings: Brian Jensen JANUARY/FEBRUARY 2003 81 step back over to the opposite wall before he can make the box move left. The gap he must traverse is backlash. It is a dead spot: Although the man is moving, the box is not. This is why a threaded shaft that is worn may feel like it has a mushy or dead spot when you change directions.

Backlash also can cause false readings on an adjustment scale, such as planer blade height. The scale may indicate that you moved the blade 1 ⁄32 in., yet the blade cuts nothing, or, worse yet, it suddenly bites off 1 ⁄8 in. It can plague the tilting table on a bandsaw or drill press, causing the table to shift or drop unexpectedly.

From Fine Woodworking #161

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Festool Cleantec CT 26 E HEPA Dust Extractor

Fein Turbo II HEPA Wet/Dry Dust Extractor

Bosch 12V Trim Router

Log in or create an account to post a comment.

Sign up Log in