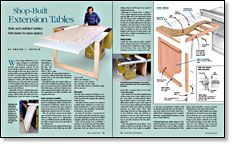

Shop-Built Extension Tables

Side and outfeed tables fold down to save space

Synopsis: This design for collapsible outfeed and side tables for the tablesaw makes it easy and safe to cut large sheet goods and other unwieldy stock when working alone in the shop. Its fold-down design also ensures that it won’t eat up valuable space in your shop. Detailed plans and instructions will give you the confidence to put greater tablesaw capacity within your reach.

From Fine Woodworking #163

When using a tablesaw to cut a large workpiece or a full sheet of plywood, it’s important to provide extra support surfaces for the stock. But like many woodworkers, I don’t have enough room in my shop to have extension tables permanently fixed in place. So after I recently added a new fence system to expand the ripping capacity of my tablesaw, I built a side table that readily folds down out of the way when not needed. This foldable table allows easy access to my grinding wheel, which is located adjacent to the tablesaw.

And while I was at it, I replaced my somewhat flimsy portable outfeed roller with a sturdy outfeed table that folds down behind the saw. I have the option of opening it in two stages, depending on my needs at the time. The first stage provides a 36-in. main outfeed table; the next stage produces a secondary outfeed table that adds about another 30 in. to the main table, handy for extralong stock.

Although the side and outfeed tables enhance the versatility of my tablesaw, the impact on shop space has been minimal. With both tables open, a 4×8 sheet of plywood remains supported throughout the entire cut. Yet, when folded, the tables add little to the footprint of the saw.

Remember that the drawing dimensions are based on building the tables to fit my 10-in. Powermatic 66 tablesaw, which sits on a 2-in.-tall wood frame. The extra couple of inches raises the top of the table to 36 in., a height better suited to my 6-ft. 4-in. frame.

Also, the rip-fence system on my tablesaw is made by Biesemeyer. If you use a different type, unless it’s a Biesemeyer clone, you’ll likely need to modify the way the tables connect to the saw, especially at the outfeed end.

Finally, because the outfeed table sits just behind the saw when folded up, the table won’t work with a saw that has a motor or any other obstruction sticking out the back. The side table, however, should be adaptable to any saw.

The side table consists of a tabletop, a connector that joins the tabletop to the saw and a side leg frame that supports the tabletop when it’s open.

The table and the connector are made of a maple frame rabbeted to accept 3⁄4-in.-thick particleboard. To create a smoother surface with extra durability, I added plastic laminate to the top face. To make the leg frame, I cut grooves in 1-1⁄4-in.-thick maple rails and stiles to accept a 1⁄4-in.-thick maple plywood panel. For added strength, I glued the panel into the grooves. Once the leg frame was assembled, I joined it to the outboard end of the tabletop with a piano hinge.

For the full article, download the PDF below.

Fine Woodworking Recommended Products

Woodriver Rechargeable Desiccant Bag

WoodRiver Router Bit Storage Case

Log in or create an account to post a comment.

Sign up Log in