Lamination Bending

Produce strong, tightly bent parts with minimal springback

Synopsis: Lon Schleining wrote a book on bending wood; in this article, he shares his tips on lamination bending as an economical way to create bent-wood furniture parts that feature woods with interesting grain patterns. The article tells how to create a bending form, cut thin plies on a bandsaw and thickness planner, glue the plies with gap-free results, and how to clean up the edges. There are also suggestions on the best glues to use, which makes a difference in this form of bending.

From Fine Woodworking #164

When it comes to making curved furniture parts, woodworkers have several options: They can cut or shape the curve from a single, thick piece of wood, or they can steam the part to make it pliable enough for bending. Some woodworkers cut a series of thin sawkerfs into the back of a piece of wood to make it bendable. And finally, there is lamination bending.

For many applications, I find that lamination bending—in which thin plies of wood are glued up on a curved form—is often the best method. It uses material efficiently and produces tight curves with little springback.

The procedure is simple. Glue is applied to all of the plies, then they are stacked and clamped around a curved form. The piece ends up with the same curve as the form.

This technique is a good way to bend woods that feature interesting grain patterns, like curly or bird’s-eye figure. You pay a premium for such wood, so cutting the curved piece from a single thick board can get rather expensive. And that fancy grain doesn’t hold up well to the stresses of steam-bending. But by gluing up a stack of plies to make a curved piece, you need only use the figured wood for the show side of the workpiece. The inner plies can be any straight-grain wood. You end up with a strong part that looks like a solid piece of expensive wood.

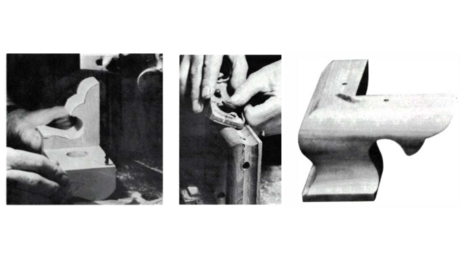

To control the shape of a bend until the glue dries, you’ll need a bending form. A typical form consists of a solid core with several outer segments. The core, often called the male form, matches the inside shape of the bend, while the outer segments, the female forms, match the outside shape of the bend. Particleboard, plywood and medium-density fiberboard (MDF) all are acceptable materials for making a form.

When clamped to the plies placed on the core, the outer segments serve as clamp pads, distributing the pressure evenly along the full length of the workpiece. With this method, all of the laminations end up squeezed tightly together, ensuring a good glue bond.

For the full article, download the PDF below.

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in