Stringing and Banding Made Easy

Low-tech tools deliver high-style results

Synopsis: Dan Faia explains how simple tools and methods can help you embellish your furniture with stringing and banding. Its less difficult than it appears, and he shows why and how you can achieve good results. One trick he shares, among multiple keys to success, is how using an ordinary pasta maker can cut veneer easily and neatly. He demonstrates the intricate work that lends flair to otherwise ordinary furniture.

From Fine Woodworking #166

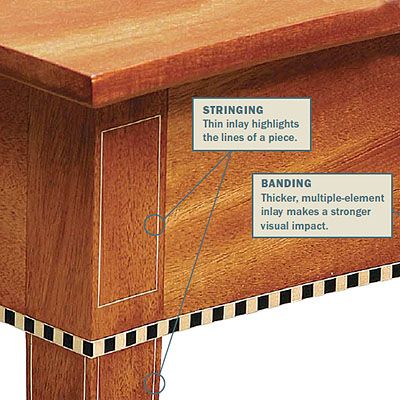

As woodworkers, we often look for ways to embellish. An easy way to accomplish this is the use of stringing and banding. Stringing can accent a tapered leg or highlight a tabletop. Banding can add colors and patterns for a rich look. These decorative details add an extra touch that makes a simple piece a striking one. In fact,they are most of what separates Federal furniture from Shaker-style pieces.

The table featured here (built by John Louchheim) has stringing and banding on the legs and aprons. As is the custom with Federal furniture, the apron banding continues across the legs, and stringing rectangles in the upper legs reflect the lines of both the legs and the aprons. This ornamentation is placed only on the most visible surfaces; for example, the banding at the bottom of each leg does not continue around the back, and the stringing rectangles are placed only on the front faces o fthe front legs.

The beauty of stringing and banding is that installation is less difficult than it appears. There are some simple tricks for making stringing, assembling the banding, and installing both types of inlay, and masking tape is theo nly clamp you will need.I inlay the stringing first and then cut cleanly across it to install the banding. At this point the table has only been dry-fitted.To inlay stringing and banding on an assembled table would be difficult.

Stringing material is cut from a sheet of veneer. The fastest way to handle this job is to use a pasta machine, which will yield enough stringing from one sheet of veneer to last for years. These machines sell for $30 to $40 at department stores and kitchen specialty stores and basically draw a thin sheet of pasta between two rollers, one of which has blades that separate the sheet into strips. Feed wood veneer into the machine, turn the crank, and perfectly sized stringing comes out the other side.

There are a few keys to success. The veneer must be cut to width to fit into the pasta machine. The veneer also has to be moist, so dampen both sides with warm water using a damp rag or a mist bottle.

For the full article, download the PDF below.

Fine Woodworking Recommended Products

Bahco 6-Inch Card Scraper

Whiteside 9500 Solid Brass Router Inlay Router Bit Set

Log in or create an account to post a comment.

Sign up Log in