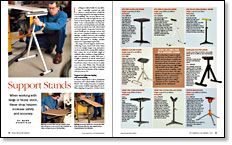

Support Stands

When working with large or heavy stock, these shop helpers increase safety and accuracy

Synopsis: In this article, we’ve tested a selection of support stands and spell out the virtues and drawbacks of each. Mark Schofield details the features on each stand, what to look for, the pros and cons, and which projects they complement. Based on this market review, Fine Woodworking’s shop manager then built a stand that combines the best features found on ones in the market, and the article includes complete instructions for building it. You’ll wonder how you ever worked without one!

From Fine Woodworking #166

Lacking an outfeed table for my tablesaw, I carefully coached my wife where to stand and how to hold the wood being ripped for the large bookcase I was building. The cut was almost completed when my wife brought the two cut sections back together again, trapping the blade. Voice communication was impossible over the screaming blade and earmuffs, and both my hands were full, which ruled out hand signals. Desperate head movements finally got the message across, and the cut was completed without too much damage. I realized, however, that avoiding strain on my marriage as well as on the tablesaw depended on finding another method for supporting long boards.

The range of work-support stands is bewildering. Some stands fold away when not in use, height ranges vary, and prices run from under $30 to nearly $100. Surfaces that contact the wood include single or multiple rollers, medium or large ball bearings, and pivoting or stable skid tops. I bought a selection of stands, tested each one, and discovered that none are perfect, but all have virtues. If you choose to make your own, John White, Fine Woodworking’s shop manager, has built a stand that combines the best features of the commercial ones.

It often is impractical to have permanent extension and outfeed tables around a tablesaw. But cutting long pieces requires some means of safely supporting the stock. When ripping a long piece, it helps to have support both on the infeed and outfeed sides of the saw. To test height and placement of the two stands, make a dry run. The actual height doesn’t have to be smack on. The supports should be placed so that the weight of the board is borne by the tablesaw and a support stand both before and after the cut.

If you use a roller support on the outfeed side when ripping, angle it 2° or 3° toward the fence to help keep the workpiece tight against the fence. Angling the stand has no beneficial effects on board travel when using stands with skid tops or ball bearings.

However, skid- and bearing-style stands are ideal for supporting stock when crosscutting because the stand may be turned 90° to use the long axis of the top.

For the full article, download the PDF below.

Fine Woodworking Recommended Products

Olfa Knife

Tite-Mark Marking Gauge

Rockler Deluxe Panel Clamp

Log in or create an account to post a comment.

Sign up Log in