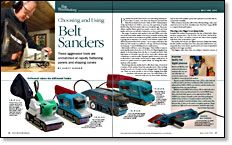

Choosing and Using Belt Sanders

These aggressive tools are unmatched at rapidly flattening panels and shaping curves

Synopsis: Belt sanders have long been a mainstay tool for tasks such as flattening glued-up panels, removing mill and burn marks, or evening up two joining surfaces. In this overview, Scott Gibson, a regular contributor to Fine Woodworking, sorts through the different sizes and features of belt sanders available to woodworkers, and tests models from seven manufacturers—Bosch, Makita, Craftsman, DeWalt, Hitachi, Porter-Cable, and Ryobi—examining the effectiveness of dust collection and stock removal on each. Also included are tips for shaping curves and flattening stock, and a look at sanding frames, which add stability when sanding flat panels.

From Fine Woodworking #170

Portable belt sanders have been a woodworking mainstay for more than 75 years, ever since Art Emmons invented the Take-About Sander for Porter-Cable in 1926. Cabinetmakers of the day forked over $130 to own one, the equivalent of nearly $1,300 today. The belt sander truly was a breakthrough. These machines rapidly flatten glued-up panels, remove mill and burn marks, and even out rail-stile connections on doors and cabinets.

The surge of random-orbit sanders in the mid-1980s took a bite out of the belt-sander market. Ever more powerful random-orbit sanders can remove stock almost as quickly, and they are less likely to gouge the work surface. As a result, some furniture makers have all but abandoned their belt sanders. I won’t argue with them. But when my belt sander succumbed to old age and frozen bearings not long ago, I started thinking about a replacement.

Belt sanders still have some advantages. Their ability to remove stock rapidly makes them the tool of choice for flattening glued-up panels or for knocking down the lip on a breadboard end. They strip layers of old paint, smooth curves, and scribe cabinets and countertops to uneven walls. Clamped upside down or on its side to the bench, a belt sander can be used to shape small pieces of wood or to grind a bevel on a plane blade. Try doing that with a random-orbit machine.

Wondering what the market had to offer these days, I borrowed a variety of belt sanders from four manufacturers. After looking closely at each tool, I found a lot has changed since I last bought one. There are more models to choose from, ranging from light machines with narrow (just over 1 in. wide) belts to behemoths with 4-in. by 24-in. belts, and they may be had with variable speed and optional accessories that increase their versatility.

With assistance from the staff of Fine Woodworking, I also evaluated seven 3-in. by 21-in. machines to compare their performance.

Portable belt sanders are grouped by the size of their belts. There are four common sizes—4 in. by 24 in., 3 in. by 24 in., 3 in. by 21 in., and 3 in. by 18 in.—as well as a narrow size that is more popular with those who work metal or glass.

The smaller the belt size, the lighter and more nimble the sander. But the smallest machines have less mass and small motors; consequently, they run at slower speeds and won’t remove material as quickly as the larger machines.

For the full article, download the PDF below.

Fine Woodworking Recommended Products

Fein Turbo II HEPA Wet/Dry Dust Extractor

Milwaukee M12 23-Gauge Cordless Pin Nailer

Festool Rotex FEQ-Plus Random Orbital Sander

Log in or create an account to post a comment.

Sign up Log in