Fine-Tune Your Shop

Ingenious carts, tables, and storage solutions improve your work environment.

Synopsis: Longtime furniture maker and teacher Jerry H. Lyons shares efficient workshop solutions developed for his dream shop—a converted 3000-sq.-ft. log cabin in Kentucky. Lyons offers detailed plans for a rolling assembly cart, a wall panel that organizes hand tools, a clamping table to aid with large-scale glue-ups, and a multifunction mobile table for use as an outfeed table or workstation.

I had longed dreamed of creating a perfect shop and using it to teach woodworking. I reached that goal five years ago when I purchased a 3,000-sq.-ft. ranch-style log cabin near my home. I converted that space into a shop where I do woodwork and offer classes on the subject.

Two words describe my workshop environment: clean and organized. As long as I can remember, I have needed a place for everything and everything in its place. I may have inherited the trait in school woodshop as the student who cleaned up after every class. Or perhaps my most recent career as a training and safety consultant, declaring the benefits of organization and systemization, has rubbed off on me.

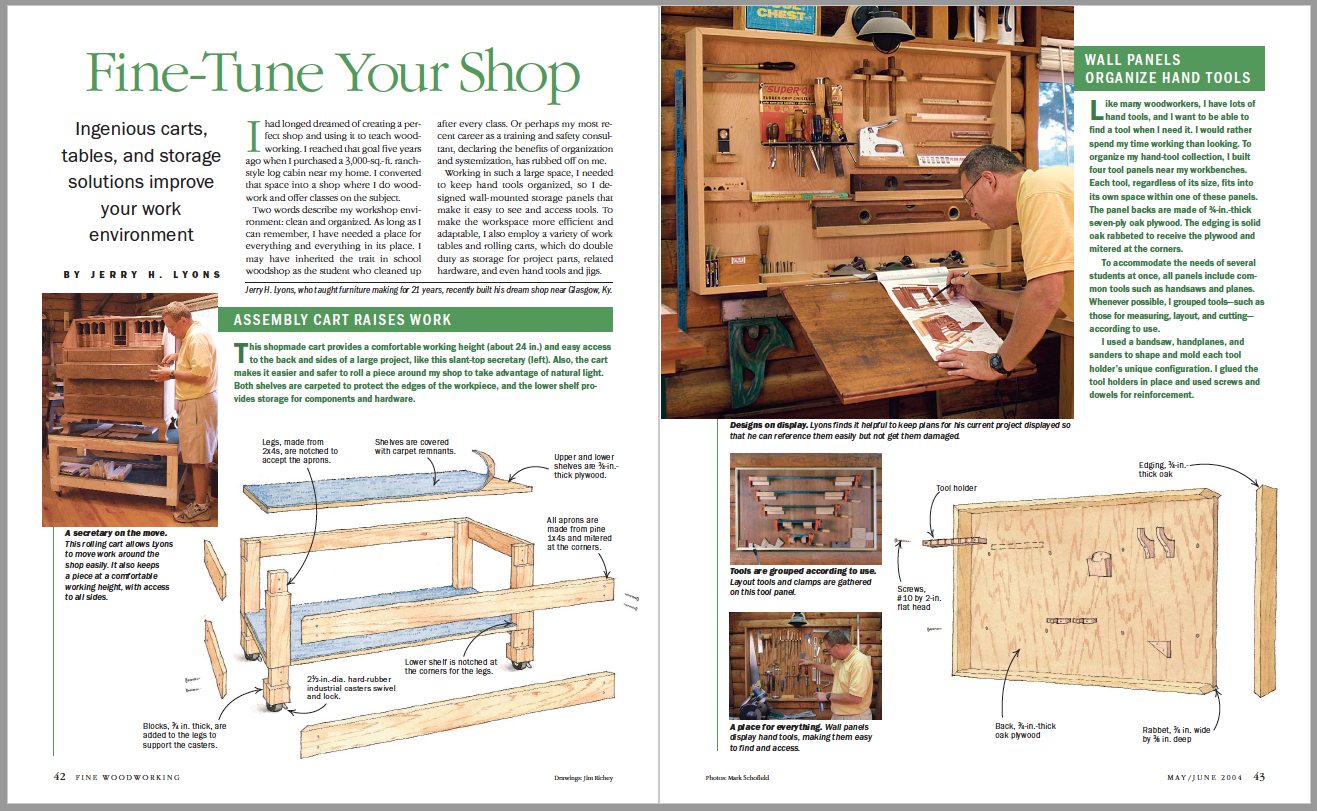

Working in such a large space, I needed to keep hand tools organized, so I designed wall-mounted storage panels that make it easy to see and access tools. To make the workspace more efficient and adaptable, I also employ a variety of work tables and rolling carts, which do double duty as storage for project parts, related hardware, and even hand tools and jigs.

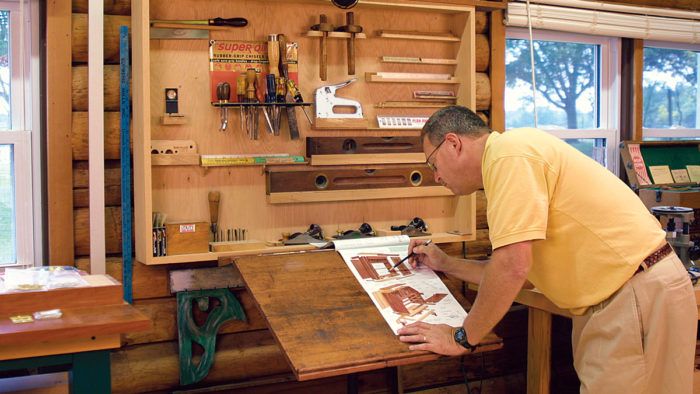

The shopmade assembly cart provides a comfortable working height (about 24 in.) and easy access to the back and sides of a large project, like a slant-top secretary. Also, the cart makes it easier and safer to roll a piece around my shop to take advantage of natural light. Both shelves are carpeted to protect the edges of the workpiece, and the lower shelf provides storage for components and hardware.

Like many woodworkers, I have lots of hand tools, and I want to be able to find a tool when I need it. I would rather spend my time working than looking. To organize my hand-tool collection, I built four tool panels near my workbenches. Each tool, regardless of its size, fits into its own space within one of these panels. The panel backs are made of 3⁄4-in.-thick seven-ply oak plywood. The edging is solid oak rabbeted to receive the plywood and mitered at the corners.

To accommodate the needs of several students at once, all panels include common tools such as handsaws and planes. Whenever possible, I grouped tools—such as those for measuring, layout, and cutting— according to use.

I used a bandsaw, handplanes, and sanders to shape and mold each tool holder’s unique configuration. I glued the tool holders in place and used screws and dowels for reinforcement.

From Fine Woodworking #170

From Fine Woodworking #170

For the full article, download the PDF below.

Fine Woodworking Recommended Products

WoodRiver Router Bit Storage Case

Woodriver Rechargeable Desiccant Bag

Log in or create an account to post a comment.

Sign up Log in