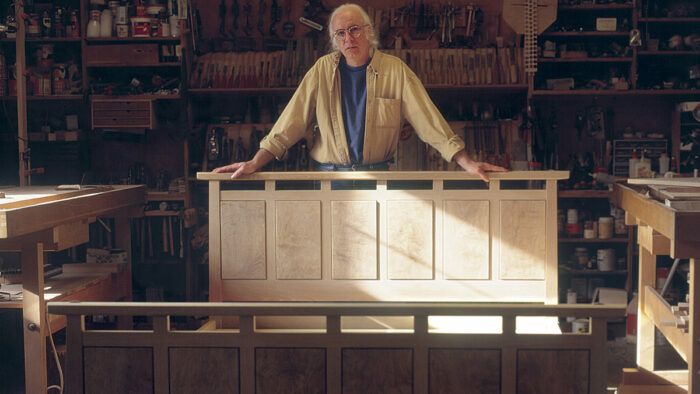

Talking Shop with Hank Gilpin

If he were a piece of wood, he would be, "White oak-wire brushed and without a finish. That's me."

Synopsis: Hank Gilpin has been making custom furniture in a converted church in Lincoln, R.I., for three decades. He sat down with former Fine Woodworking editor Jonathan Binzen to discuss the influence of his mentor, Tage Frid, his focus on building with solid wood only, the use of hand tools vs. machine tools, and his advice for those who want to pursue a professional woodworking career.

Jon Binzen: Your mentor, Tage Frid, taught the whole gamut of woodworking techniques, yet you focus strictly on solid wood. How did you develop that approach?

Hank Gilpin: When I was in graduate school in the early ’70s, everyone was doing Art Nouveau-inspired work. All kinds of flowing lines, awfully difficult things—laminating, steam-bending, and veneering—all that stuff that’s so outrageously time-consuming. When I opened my shop, economic forces dictated simplicity. If I could sell a piece of furniture for $200, I was really pushing it. So I became Mr. Mortise-and-Tenon and Solid Wood.

At one point in the early days, I had a one-curve rule. I realized that if a piece had more than one curve in it, I wasn’t going to make any money. Then I took it a step further and said, OK, there can’t be any curves. This has to be straight-line design. I have to design pieces that are out of the planer and the tablesaw, and still have some kind of interest. They could have a million tenons and mortises because I could whip through those. Obviously, I abandoned the no-curves rule, but it was good discipline.

JB: How do you see yourself in relation to your contemporaries who make more sculptural, self-expressive furniture?

HG: Early on I realized that I’m either not interested enough or not talented enough to do a certain type of expressive work, but I’m really good at another type: the simple, practical pieces that have a little bit of zing to them. Compared to what other people were making, these were somewhat lesser-priced, functional pieces.

JB: What is on your mind when you design?

HG: I listen very carefully to what a client says to me. Then I look around and get a feel for what they are all about, and I try to make something suitable in my own way. I never ignore the client’s needs. That’s the practical aspect, and it’s a big, powerful force. They’ve got to be able to sit at this table. They don’t want it talking to them when they’re sitting at it.

JB: You are contacted frequently by aspiring woodworkers. What do you say to someone who tells you they want to do what you do?

HG: I’m brutally honest. I tell them it’s impossible. Then I work backwards from there. If you want to make a living making wooden objects, there are some absolutes to consider: You’re not going to make a lot of money for 10 years, if ever. You have to be totally dedicated to your work; your life is secondary. You have to live and work in the same place. You have to work more than anybody else. I work 60 to 70 hours a week. I don’t mind. I don’t watch television, so I have plenty of time to draw, sketch, and think. Every night I’m doing my little business.

For the full article, download the PDF below.

Fine Woodworking Recommended Products

Stanley Powerlock 16-ft. tape measure

Drafting Tools

Compass

Comments

Wait - what??!! The PDF is 4 pages, but the story is obviously longer. Where's the rest of it?

Log in or create an account to post a comment.

Sign up Log in