A Shop on Top

Raising the garage roof creates space for a second-story shop

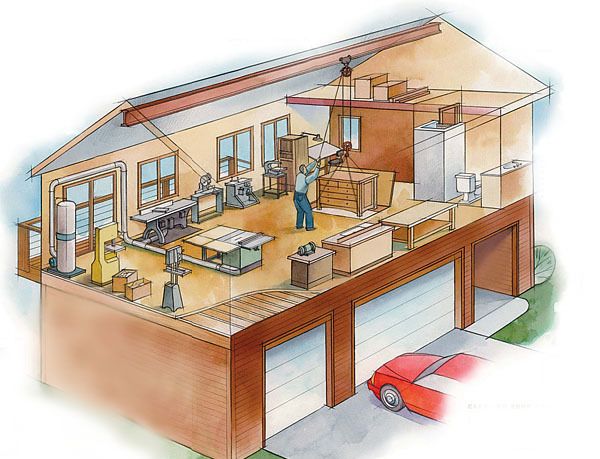

Synopsis: In need of room for a shop but lacking space on his property to build one, Paul Breskin decided to look up rather than out. He expanded his single-story, three-bay garage upward, producing space for a roomy, 800-sq.-ft. shop. Extra-beefy floor joists and thick plywood flooring accommodate heavy loads from shop equipment, and a trapdoor complete with chain hoist makes short work of bringing heavy items up from the first floor. A bathroom with shower, and lots of light and ventilation complete the package.

For a good many years, I was able to get by with my three-car garage doubling as a workshop. And while all the shuffling of cars and woodworking machines made that shop far from a perfect arrangement, it provided enough space to satisfy most of my woodworking needs.

Eventually, though, as I spent more time in the less-than-ideal confines of a garage, I began to recognize the many advantages of a standalone shop. But there was a problem: I didn’t have room on the property to expand outward. That’s when I realized my dedicated shop could be had by adding a second story to the garage. Although some might consider the solution unorthodox, it provided me with an additional 800 sq. ft. of open space to devote entirely to my shop.

Like any major building project, this one came with an assortment of challenges. For starters, the foundation needed major modifications to meet building-code requirements related to the added weight of a second story. Also, because the second floor had to support a 16-in. jointer that weighs more than 1,800 lb., the floor joists had to be 2×14 lumber placed 12 in. on center, instead ofthe more common requirement of 2×12 lumber placed 24 in. on center. I also had to use 11 ⁄4-in.-thick tongue-and-groove plywood for the floor, instead of the normal 3 ⁄4-in.-thick plywood.

Support posts always seem to get in the way in a woodworking shop. To avoid having any, I substituted an 8-in. by 16-in. steel I-beam for the typical wood ridge beam. The I-beam also served as a place to mount a chain hoist with a trolley. The trolley lets me run the hoist along nearly the full length of the shop.

To help contain shop noise, I insulated the floor, ceiling, and walls. Now, as long as the windows are closed, I can work in the shop any time of the day or night without bothering my neighbors.

Compressors are noisy, and mine is no exception. To give my ears some relief, I installed the compressor below the shop, in the garage. I use the same area for lumber storage.

The exterior of the shop, including the windows, was designed to complement the look of the house. A lot of natural light bathes the shop, thanks to a generous number of windows, plus a sliding glass door and three skylights. To help minimize noise, all of the windows, doors, and skylights are double-paned.

Thanks to all of the glass, I rarely need to have lights turned on during the day. Keep in mind, though, that windows have one drawback: They reduce wall space. And walls are great places to hang tools or mount storage cabinets. In my shop, the walls are constructed of pine boards installed horizontally. Not only does the pine give the shop an appropriate look, but it’s also a surface that readily accepts screws, nails, and pegs to hang tools.

From Fine Woodworking #174

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in