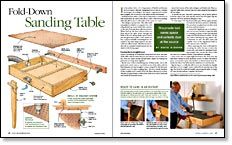

Fold-Down Sanding Table

Shopmade tool saves space and collects dust at the source

Synopsis: David DiRanna’s fold-down sanding table does more than protect his lungs from wood dust, a carcinogen. Mounted to the wall on a simple bracket system, it folds flat when not in use, saving valuable shop space. The dust collector is essentially a shallow rectangular box with a Peg-Board top that draws air and dust down through the holes as a piece is being sanded. Inside the box, a plywood baffle helps direct dust toward the port.

In December 2002, a U.S. Department of Health and Human Services report officially designated wood dust as a human carcinogen. According to the report, “unprotected workers have a higher risk of cancers to the nasal cavities and sinuses.” Such blunt facts make it clear that it’s important to control wood dust in the shop. As part of that effort, I built a fold-down sanding table that allows me to collect dust at the source as I sand.

The design is pretty basic. The table itself essentially is a shallow rectangular box with a Peg-Board top. A port in the side connects to the hose from my dust-collection system. When fired up, the dust collector draws air from above the table down through the holes in the top, taking along a good deal of the dust generated while I sand. Inside the box, a plywood baffle extending from one corner to the other helps improve the dustcollection effectiveness. The table mounts to the wall via a simple bracket system (see the detail on the facing page).

Construction is straightforward

I own a dovetail jig, so it was easy to join the front, back, and sides of the table with dovetails. But you don’t have to use dovetail joinery. You can create strong-enough joints simply by butting the parts and screwing them together.

By the way, before assembling any of these joints, use a drill press and a circle cutter to cut a hole in one of the sides, with the hole diameter just big enough to create a snug fit for the dust port. I used a 3-in. PVC pipe coupling here. The 4-in. outside diameter of the coupling was a perfect fit for the dust collector’s 4-in. hose. This also is a good time to drill a hole at the back end of each side and install the threaded inserts.

Attach the bottom of the table with glue and finish nails. Then secure the baffle with a bead of silicone caulk along the full length of all four edges.

To mount the port, first add a generous coat of epoxy glue to both the edge of the hole and the end of the PVC pipe. Slip the pipe into the hole and allow the glue to dry.

From Fine Woodworking #174

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Festool DF 500 Q-Set Domino Joiner

WoodRiver Router Bit Storage Case

Festool Cleantec CT 26 E HEPA Dust Extractor

Log in or create an account to post a comment.

Sign up Log in