User’s Guide to Plywood

For furniture makers, sheet goods offer strength, stability, and good looks

Synopsis: Sometimes solid wood is not the best option. For built-in cabinets or large tabletops, for example, contributing editor Roland Johnson turns to plywood. Its sandwich structure of thin veneer layers makes it flat and stable. With a high-grade hardwood veneer, plywood looks great and saves time and money. It’s stronger than regular wood, holds a screw well, and makes great door panels, drawer bottoms, and cabinet backs. It’s also good for making strong and stable jigs. Johnson explains how to choose hardwood-veneer plywood, how to cut big sheets safely and without tearout, the best joinery for plywood, and how to apply edging.

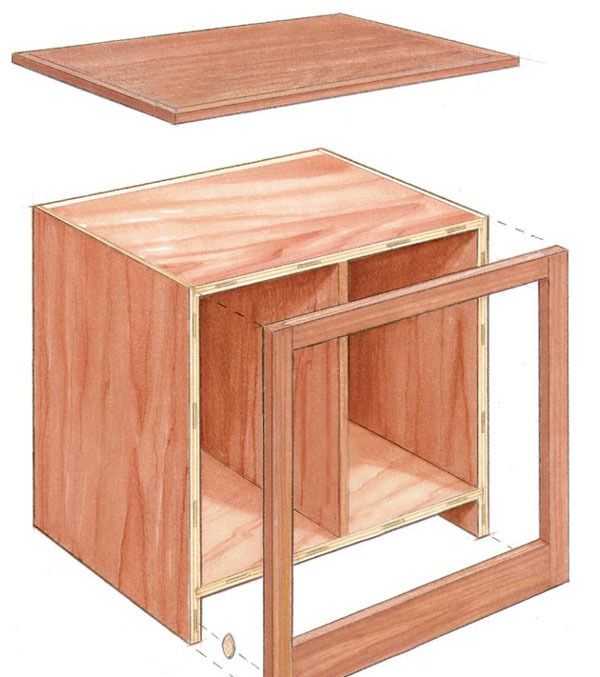

As much as I enjoy building furniture out of solid wood, there are times when it is not the best choice of material. When I make built-in cabinets or large tabletops, I turn to plywood. Its sandwich structure of thin veneer layers, with the grain oriented at right angles, makes plywood flat and stable. When faced with a high-grade hardwood veneer, plywood looks good and saves time and money.

Plywood also is structurally stronger than natural wood and has excellent screwholding capabilities. It is also ideal for door panels, frame panels, drawer bottoms, and cabinet backs. As a shop resource, plywood makes strong and stable jigs and fixtures that are inexpensive to build and easy to modify.

How plywood is graded

The best way to buy plywood is to select sheets individually from a dealer with a good inventory. If that is not possible, it helps to know what to ask for.

If you’re ordering plywood sight unseen from a distributor, you’ll want to specify several things, including the quality of the veneer on the sheet’s face and back (the face is generally better looking) and the composition and quality of the plywood’s inner core.

The Hardwood Plywood and Veneer Association (HPVA; www.hpva.org) sets standards for grading hardwood-veneer plywood based on how free the surfaces are of defects such as knots, patches, and color variations. Grades for face veneer begins with AA for the best quality and run down to grade E, which can include unlimited color variations and patches. The back veneer is number graded, with grade 1 being the best and grade 4 allowing knotholes, splits, and other defects.

You also should select plywood with a core that’s as uniform and free of voids as possible. In the HPVA grading system, J signifies the best core material with no voids in the plies. Cores step down in quality to grade M.

From Fine Woodworking #177

For the full article, download the PDF below:

Fine Woodworking Recommended Products

AnchorSeal Log and Lumber End-Grain Sealer

DeWalt 735X Planer

Ridgid R4331 Planer

Log in or create an account to post a comment.

Sign up Log in