A Little Masterpiece

Block-front document cabinet will challenge your skills

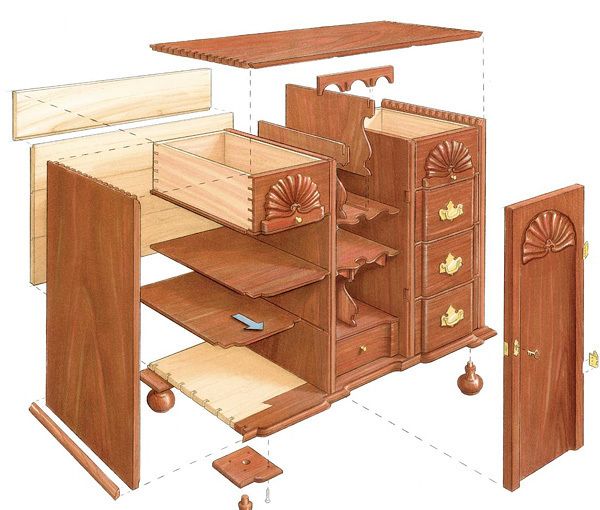

Synopsis: With three carved fans and 271 hand-cut dovetails, this 1750s mahogany and pine document cabinet is for those who want to take their woodworking skills to a new level. Period furniture maker Randall O’Donnell takes you through the step-by-step process of building this little masterpiece. By the time you are finished, you will not only know the techniques for crafting a Newport block-front case piece, you’ll also have created an exquisite piece of furniture.

As much as any known specimen, this 1750s document cabinet displays the creativity of the Rhode Island block-front style. Exquisitely crafted, this small piece possesses the features of the very best furniture made by the very best craftsmen. Most of the techniques are similar to those required to build any Newport block-front case piece. However, while you will save on materials, don’t expect to save on time: The details and construction on such a small scale are very challenging (besides carving three fans, there are 271 hand-cut dovetails). This project will push your woodworking skills to a new level, but you will be rewarded with an exquisite piece of furniture.

Start with the carcase and its dividers

The 15 half-blind dovetails that join each corner of the carcase typify the no-expense-spared tone of the design. The half-pins at the front allow for the mitered corners, and those at the back accommodate the rabbet. The miter is not at 45º, because it starts 1⁄4 in. from the outside edge of the sides.

Once the carcase has been dry-fitted, rout the grooves for the main vertical dividers and the drawer dividers, stopping short of the front edge. The V-shaped terminus for the drawer divider grooves is made with a chisel and a mitered scrap block. Work a fillet and quarter-round on the inside edges of the carcase and on both sides of the vertical dividers.

The base is pine with a front section of mahogany. Unlike the original, I joined these two pieces with the giant dovetail more commonly seen in Boston case work because I think this is a superior construction method. You can cut the front molding on the mahogany either before it is joined to the pine or after the whole base has been dovetailed. I used a router to establish the fillets and flats and then hand-carved the remainder. Once all of the dadoes and carving are done—but before gluing the carcase together—run a rabbet inside the back edges to accept the back boards.

With the carcase glued, make the partitions. The drawer dividers on both sides of the center compartment are identical. Unlike the original antique, where the dividers are about 7 in. wide, on this piece they run to the back of the case.

From Fine Woodworking #178

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Blum Drawer Front Adjuster Marking Template

Circle Guide

Dividers

Log in or create an account to post a comment.

Sign up Log in