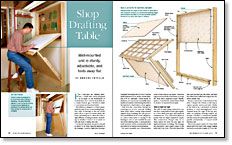

Shop Drafting Table

Wall-mounted unit is sturdy, adjustable, and folds away flat

Synopsis: If you enjoy designing woodworking projects with a pencil and straightedge, you’ll want to see the plans for Dwayne Intveld’s drafting table. This convenient and functional station features torsion-box construction. It is mounted to the shop wall and can be adjusted to eight different working positions. The top is hinged to a lower panel, and both parts fit into a frame so it can be folded flat against the wall (with the drawing still visible) when not in use. The design also features storage space for pencils, erasers, rulers, and drawings.

For a long time, my “drafting table” was a small sink cutout propped at an angle on my workbench. It worked okay, but it was far from ideal. So a couple of years ago, I decided to make a convenient and functional table.

The tabletop is hinged to a lower panel, and both parts fit into a surrounding frame. Two pairs of bearings at the top of the table roll in a groove routed inside the frame, permitting me to adjust the table to eight different working positions, depending on whether I want to sit or stand, or how my back is feeling that day.

For smooth operation, the groove should be about 1⁄32 in. wider than the diameter of the bearings. I used two light-duty bearings (available from Reid; 800-253-0421) with an inside diameter of 1⁄4 in. and an outside diameter of 3⁄4 in. Although I chose maple for the frame, you can use any reasonably dense hardwood, mainly so the bearings that ride in the track have a hard surface to bear against.

Drill 1⁄4-in.-dia. cross-holes through the routed groove at 6-in. intervals. Drilling these holes before routing helps prevent chipout from breaking into the groove. Two small fillister-head screws slipped into a pair of these holes act as pegs for the bearings to rest on and establish the position of the drawing table. A cupboard-door catch mounted on the crossmember holds the table in its vertical stored position.

For quick assembly, use a biscuit joiner on all of the joints in the frame. Then rout a groove in the back of the frame to accept the 1⁄8-in.-thick pegboard panel. Finally, apply a water-based polyurethane finish to protect all exposed wood parts.

Table is light but rigid

The table is made using torsion-box construction. Using half-lap joints, glue together a 3⁄4-in.-thick pine grid and sandwich it between two 1⁄4-in.-thick birch-plywood panels with the edges trimmed in maple. This construction, though only 11⁄4 in. thick, keeps the table flat and light yet rigid and resistant to twisting.

From Fine Woodworking #179

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Incra Miter 1000HD

Log in or create an account to post a comment.

Sign up Log in