All About Bending Wood

Bending wood doesn’t require superhuman strength. There are a few common recipes and procedures that can be employed to create curved parts from straight boards. In this article we’ll go through the pros and cons of steam bending, a process of heating and moisturizing wood until it is flexible, lamination, the process of gluing multiple thin, flexible boards together over a curved form, and sawing, cutting curves directly out of flat stock.

The Basics:

• Steam it: Heat and humidity will make a board ripe for bending.

• Laminate it: Clamping a stack of thin strips to a form is an alternative method for creating curved parts.

• Saw it: Cutting a curve directly out of flat, square stock is always on option, but not always the best one.

Steam it

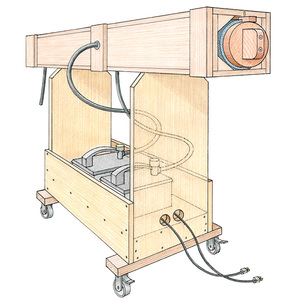

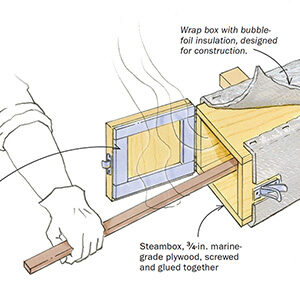

Steaming uses steam or boiling water to make the wood pliable so that it can be bent to a form. Once cooled, the bent piece will retain its shape. There are advantages to this method: It retains the continuous long-grain pattern, there are no glue lines, and it doesn’t waste material. Steaming does have some drawbacks: It’s difficult to contain springback, which means the form may lose some of its shape, and pieces can break if there are any defects or issues with the orientation of the grain. You can reduce breakage by using straight-grained lumber with no grain runout. Grain runout refers to areas of a board where the grain ends along the edge. Wood will bend when steamed at a temperature of about 200°F. The length of time it must steam depends on the thickness of the workpiece; it can range anywhere from 20 minutes for a 1/4-in. chair-back slat to one hour for a 2-in. thick chair post. Steam boxes are relatively easy to make with supplies available at the hardware store; they are also commercially available.

Laminate it

Another method for bending wood is to resaw several thin pieces of wood and laminate them clamped to a form. When the glue dries, you’re left with a single piece that holds the shape of the form. Preparing the thin pieces for a lamination involves resawing a piece on the tablesaw or bandsaw. The drawback here is that you lose a lot of material to the kerf of the sawblade. Springback is not a major concern when making a bent lamination, especially if you use a rigid polyurethane- or resin-based adhesive. Not only do these glues hold their form, but they also prevent the layers of the lamination from slipping and losing their form over time, a process known as creep.

Saw it

You can always cut a curved shape out of a square one, but what you may gain in simplicity, you will lose in strength and durability. Both steam bending and lamination have the benefit of manipulating the wood so that the grain follows the curve and is continuous across the whole part. This is especially important on structural elements like chair legs and backs, when the curved piece is going to be supporting weight and taking stress. On a sawn part, some parts of the curve may become weak as the grain cuts across the part, instead of flowing with it.

Need help deciding which method to use? Check out Brian Bogg’s article about creating curved furniture.

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in