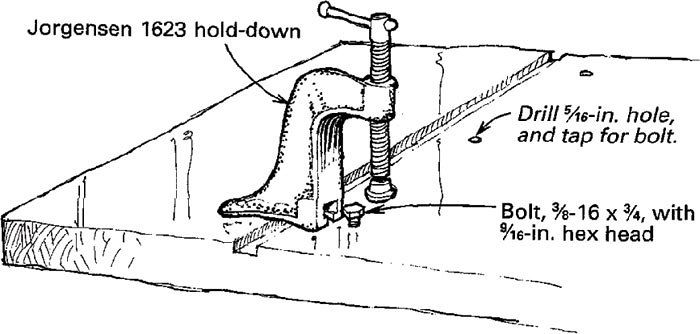

A Table Saw Clamp

Because space has always been a concern in my small shop, the top of my tablesaw has often served second duty as a workbench. I found that by securing removable Jorgensen model 1623 hold-down clamps to the saw table, I could make the saw into a workbench without affecting its intended use. Four tapped holes in a saw table allow a surprisingly versatile choice of clamping positions. I also use the holes to bolt a protective piece of plywood to the saw table for chisel work, to attach a router table and to secure featherboards and other tablesaw jigs and fixtures.

When locating the clamp’s hole positions, be sure to avoid the cast reinforcing ribs in the table’s underside. Center punch each hole location, and then drill with a sharp 5/16-in. bit. When tapping the 3/8-in. bolt threads, rotate the tap a half turn in, then back it out a quarter turn, and so on. This action will break up the chips and keep the tap cutting freely. Don’t force the tap, and when you’re done, chamfer the hole to keep any sharp edges from scratching your workpieces. Screw a 3/8-in. bolt with a 9/16-in. hex head into the threaded hole. Leave the head of the bolt slightly above the table, so the slot in the clamp can be slid over it. The size of the slot just fits the head on the bolt and thus becomes a sort of wrench for tightening the bolt.

Steve Acker, Arlington, Tex.

Fine Woodworking Magazine, December 1992 No. 97

Fine Woodworking Recommended Products

Woodriver Circle Cutting Jig

Hedgehog featherboards

Milescraft 4007 6in Bench Clamp

Log in or create an account to post a comment.

Sign up Log in