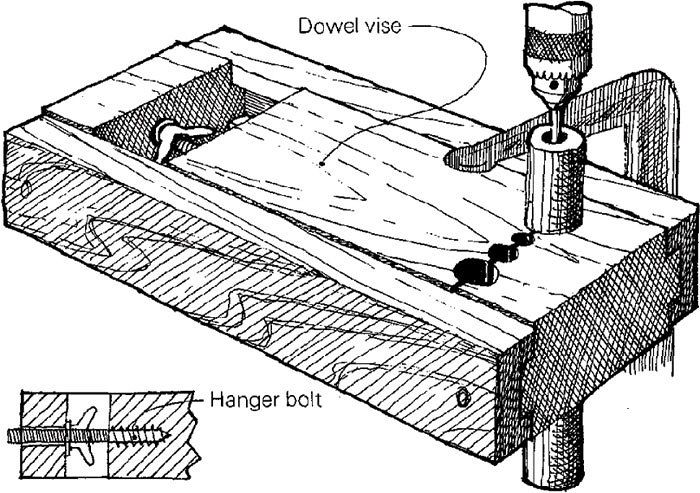

A Vise for End-Drilling Dowels

The vise shown in the sketch makes easy the awkward operation of drilling holes in the ends of dowels on the drill press. The vise consists of a thick wood block and a frame. The sides of the block are keyed to and slide in U-shaped slots in the frame. The block tightens in the frame by means of a hanger bolt screwed into the tail of the block and run through an oversized hole in the frame, as shown in the detail. The vise’s jaws clamp the work when you turn a wing nut against the end of the vise frame. A washer at this point helps.

To make the vise, use a 2-in, thick hardwood such as maple or birch. Plane the sides of the frame a little thinner than the center block. This allows the sides to move easily when the center block is clamped in position on the drill-press table.

I use the vise to drill the holes for new ends on broken chair legs and spindles. The four holes in the vise jaws are sized to fit common chair parts (3/8 in., 1/2 in., 3/4 in., 1 in.) To drill the vise-jaw holes, clamp a piece of 1/8-in. scrap in the jaws and drill the four holes centered on the scrap. With the scrap removed, the holes will be undersized so that the 1-in, hole will grip a 1-in. dowel.

Leo Myers, Wellington, Ohio

Fine Woodworking Magazine, April 1981 No. 27

Fine Woodworking Recommended Products

Woodriver Circle Cutting Jig

Hedgehog featherboards

MicroJig Matchfit dovetail clamps

Log in or create an account to post a comment.

Sign up Log in