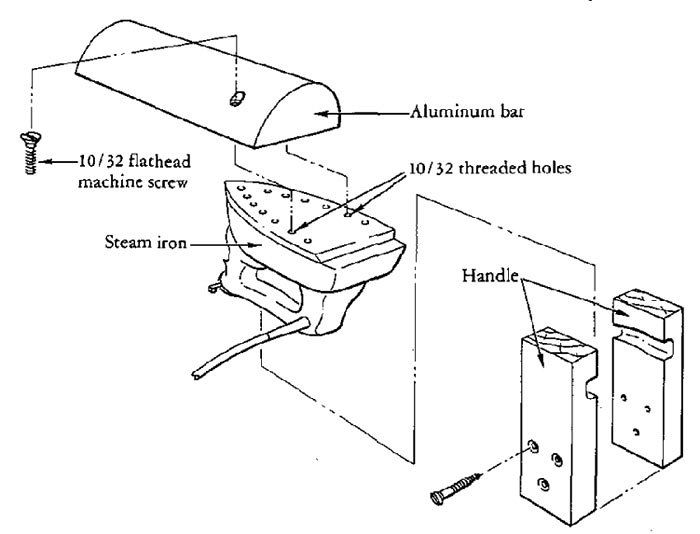

Bending Iron

I teach high-school woodworking and for the past two years have had the students design projects that require bent wood. I have tried soaking and steaming with limited results, so I designed and built a simple bending iron from an aluminum bar and an old steam iron. The wood is wet with a sponge only where it is to be bent. This eliminates the staining and raised grain caused by soaking or steaming, and it can be glued immediately if it is not wet too much. My students have used the iron to bend wood up to 1/8 in. thick for projects ranging from guitar and dulcimer sides to fishing nets.

Start with a 6-in, length of round aluminum bar, and hacksaw it in half lengthwise. Sand the cut surface smooth on an aluminum oxide belt, and file all the edges smooth. Pick two steam holes in the sole of the iron, drill them out and thread them to accept #10-32 machine screws. Drilling elsewhere on the sole risks breaking into the heating element. Thread only as deep as the original steam holes, else the tap may bottom out and break off. Now locate these holes on the bottom of the aluminum block, drill through with a 1/4-in.-diameter bit for clearance, and countersink the top of the holes for the flathead screws. The screwheads may need to be filed flush after assembly. I started with 1-1/2-in. screws and ground them to length so they would tighten in the threaded holes without bottoming. Finally, groove two chunks of 2×4 to fit around the handle of the iron, so it may be clamped upright in the vise.

David G. Johnson, Hanover, N.H.

Fine Woodworking Magazine, Fall 1977 No. 8

Fine Woodworking Recommended Products

Woodriver Circle Cutting Jig

Incra Miter 1000HD

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in