Coping Molding with a Router

A coped joint fits and looks better than a rnitered joint. So when I replaced all the base molding in my home, I decided to cope the joints at the inside corners of the rooms. Traditionally, joints are coped by first cutting a 45¡ miter on the end of one piece of molding and then using a coping saw to cut along the curved line created where the miter cut intersects the molding’s surface. This trims the end to the exact reverse section of the molding so that it will butt into the other piece of molding already installed tightly in the corner. Being fundamentally inept with hand tools, my attempts at sawing the joint fell far short of my expectations. Finally, I came up with the following router-based fixture, which makes this job more tolerable.

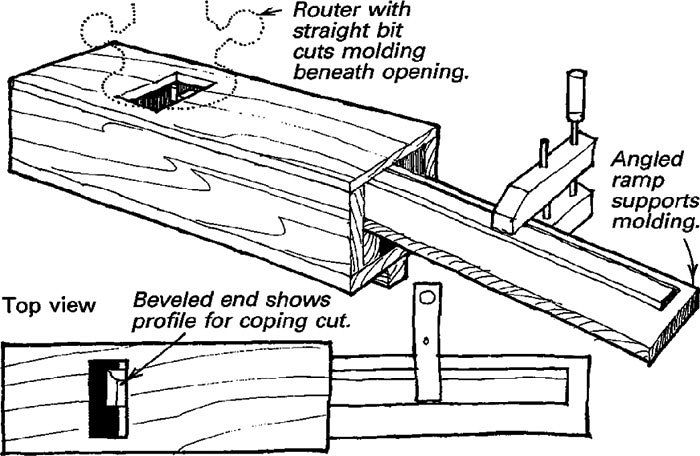

The fixture is a rectangular box with one open end, into which a wood ramp is inserted at a 20¡ angle. A rectangular hole is cut into the top of the box above the end of the ramp. A 2×4 attached to the bottom of the box enables the whole fixture to be clamped into a Work-Mate portable workbench.

To use the fixture, cut the end of the molding at 45¡ so that the profile on the end shows the area to be coped away. Alternatively, you can scribe the molding with the shape to be cut and score any straight sections with a utility knife. In either case, insert the molding into the box and clamp it onto the ramp. Chuck a 3/16-in. straight bit in a router and insert the bit through the hole in the top of the fixture. Turn on the router and follow the scribed line to cut off the end of the molding. The angle of the ramp creates a slight back cut at the shaped edge, which makes the pieces fit together better. Before unclamping the workpiece, check the fit by inserting a short piece of molding through the top. Any necessary fine adjustments can be made with a file.

Once the molding is unclamped, the coped joint should fit quite well. After the first couple of tries, I became quite proficient with this system. The cuts were smooth, and the fit was better than anything I had previously achieved with a coping saw.

Scott Ashworth, Mars, Pa.

Fine Woodworking Magazine, August 1991 No. 89

Fine Woodworking Recommended Products

Bessey K-Body Parallel-Jaw Clamp

Jorgensen 6 inch Bar Clamp Set, 4 Pack

Log in or create an account to post a comment.

Sign up Log in