Cutting Flutes on Curved Turnings

For cutting reeds and flutes in curved and tapered turnings, I use a cutter mounted in a drill press, and a special indexing jig to hold the workpiece. Although making the cutter requires some time and moderate metalworking skills (or machine-shop expense), once it is done you can cut reeds and flutes on any shape with minimal set-up and excellent results.

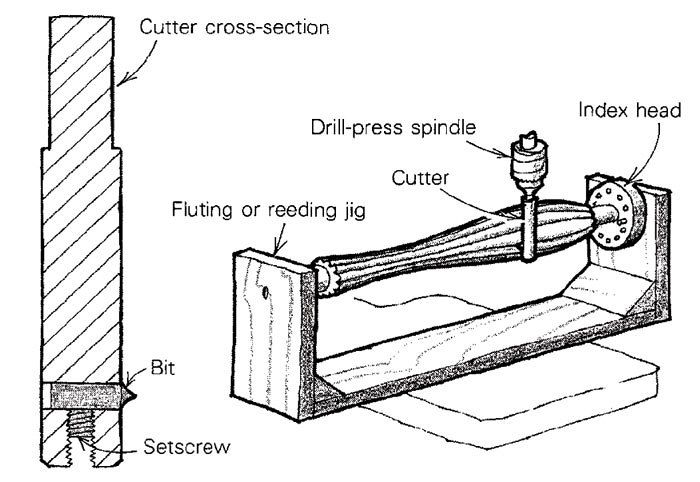

Make the cutter from a short length of 5/8-in. cold-rolled steel. Turn the top 1 in. of the cutter down to 1/2 in. so it can be chucked in the drill press. Drill a 1/4-in. hole through the cutter 1/2 in. from its bottom, and file the hole square to accept a short length of 1/4-in. tool steel for the bit. In the bottom of the cutter, drill and tap a hole for a setscrew, which holds the bit in place. Grind the bit to the shape of the profile desired for the reed or flute.

When the cutter is complete, you will also need a jig to hold the turning and to index the work as the flutes are cut. The jig can be either a simple one-time affair or of a more elaborate, permanent design incorporating an adjustable tailstock. In either case, lay out the round indexing head carefully by dividing the circle into a number of equal angles according to the number of flutes required. For example, if 24 flutes are desired, then the pin holes on the index head will be 15¡ apart. On a permanent jig, you can use one indexing head for many combinations by laying out several concentric circles of pin holes, each with a different number of holes.

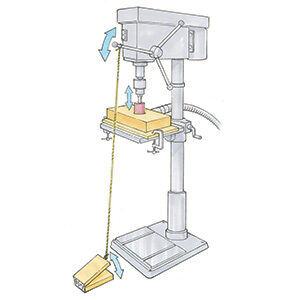

To cut the flutes, first turn and sand the workpiece, then fasten it in place between centers in the jig. With the jig in place on the drill-press table, lower the drill-press quill until the cutter bit is on the centerline of the turning. Lock the quill at this setting. With the drill press running at its highest speed, move the turning into the bit and across the table. The bit cuts the profile of the flute while the cutter body rubs along the turning, regulating the depth of cut. After the first cut, index the turning to the next hole and repeat the process until all flutes have been cut.

Kenneth Weidinger, Erlanger, Ky.

Fine Woodworking Magazine, August 1983 No. 41

Fine Woodworking Recommended Products

MicroJig Matchfit dovetail clamps

Milescraft 4007 6in Bench Clamp

Double Sided Tape

Log in or create an account to post a comment.

Sign up Log in