Dovetailing with a Laminate Trimmer

The most time-consuming part of dovetailing drawers is the tedious tap-tap-tapping with mallet and chisel to cut the half-blind pins in the drawer fronts. So, when I was faced with making eight mahogany drawers with a 1/4-in. overlay on the fronts, I decided to cut these pins with an offset laminate trimmer that I’d recently acquired. The method I devised takes advantage of the offset trimmer’s unique features: It provides excellent visibility of the bit, it is small and lightweight and it has an offset center of gravity. The resulting pins are speedily and easily cut without looking as if they were mass-produced with a jig.

First, I laid out the tails on the drawer sides using the two dovetail marking tools described in Fine Woodworking #53 on p. 51, and then bandsawed them out. Because the backs were joined with simple through dovetails, I marked the pins from the tails and bandsawed them.

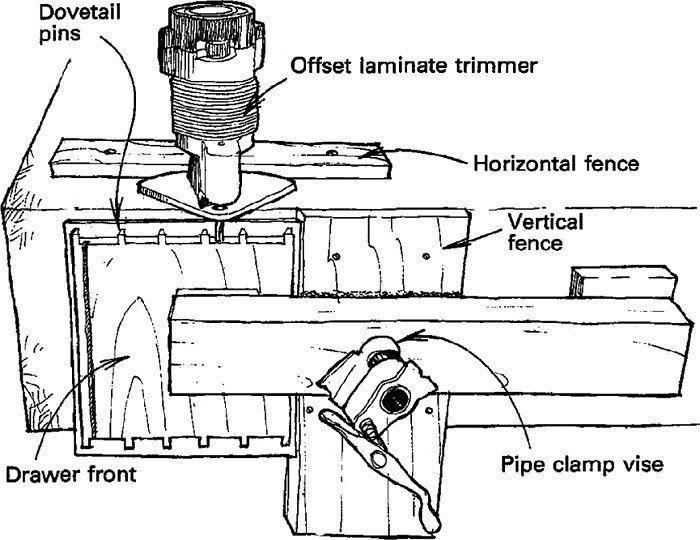

After marking the pin locations for the half-blind dovetails on the drawer fronts, I clamped one of the fronts to the side of my worktable using a special setup and pipe clamp vise, as shown in the above drawing. Two fences are key to the setup. The vertical fence is fastened to the side of the workbench and registers the drawer front to ensure that it’s perfectly square with the top of the table. The horizontal fence is screwed to the tabletop and acts as a guide to run the base of the router against. This fence is set parallel with the edge of the table and just far enough away from the edge to leave the proper lip on the drawer front. To cut the pins I chucked a 3/16-in. straight router bit in the trimmer and adjusted the drawer front in the vise so that the depth of cut was right to the line representing the thickness of the side piece. I turned on the trimmer and carefully wasted the areas between the pins by routing right up to the scribed lines. Very little trimming with a chisel was necessary to clean up the joint when the routing was complete.

The offset trimmer is particularly well suited for this kind of work because its center of gravity is over the table, not over the bit. For safety’s sake, be sure to use a face shield and goggles to keep the blizzard of little wood flakes out of your eyes.

John E. Janbaz, Amarillo, Tex.

Fine Woodworking Magazine, February 1990 No. 80

Fine Woodworking Recommended Products

Veritas Standard Wheel Marking Gauge

Starrett 4" Double Square

Festool DF 500 Q-Set Domino Joiner

Log in or create an account to post a comment.

Sign up Log in