Eccentric Router Base

This router subbase allows me to rout an “in-between” size groove (for various stock thicknesses) without moving the guide fence or changing the setup. Because the subbase is eccentric to the router bit you can change the diameter of the base simply by changing the point of the base that rides against the guide fence.

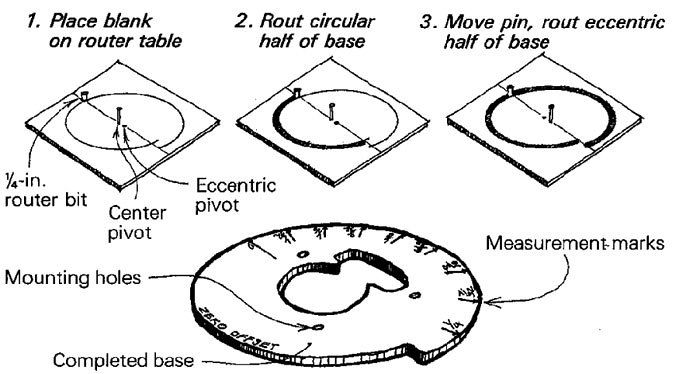

To make the base, choose plywood, plastic or a 4-ply stack of plastic laminate for the material. You can cut the eccentric shape on a bandsaw or jigsaw, but for a smoother, more accurate base use a router table to machine the base. First drill a 1/16-in. pivot hole at the center of the blank for the base and another 1/16-in. pivot hole offset from the center. The offset determines the eccentricity of the base. I used an offset of 1/8 in., which allows me to cut grooves of up to 1/2-in. with a 1/4-in. bit. On a line through these holes drill a 1/4-in. hole at a radius slightly larger than the radius of your router base. Before proceeding, it’s a good idea to locate and drill the mounting holes in the subbase.

To cut the circumference of the base, mount the blank on the router table with the 1/4-in. hole over a 1/4-in. router bit. Drill 1/16-in. holes into the router table through both the center pivot and offset pivot. Put a pin in the center hole, turn on the router and rotate the subbase 180¡. Return the blank to its starting position, put the pin in the offset hole and rotate the base 180¡ in the other direction. You will have to finish the “step” area with a file. Before routing out the center of the subbase, you should pivot the base on the center hole and scribe measurement lines on the base for every 1/32 in. of diameter change. Use a fine-tip waterproof pen.

To use the base to cut a 5/16-in. groove, for example, clamp a guide fence in place on the work and rout a 1/4-in. groove. Keep the zero-offset part of the subbase against the fence. Now rotate the base until the 1/16-in. scribe line touches the fence. Keep the 1/16-in. mark touching the fence and make another pass, taking care not to twist the router. The result is a 5/16-in. groove.

Mike Ramey, Seattle, Wash.

Fine Woodworking Magazine, October 1981 No. 30

Fine Woodworking Recommended Products

MicroJig Matchfit dovetail clamps

Woodriver Circle Cutting Jig

Milescraft 4007 6in Bench Clamp

Log in or create an account to post a comment.

Sign up Log in