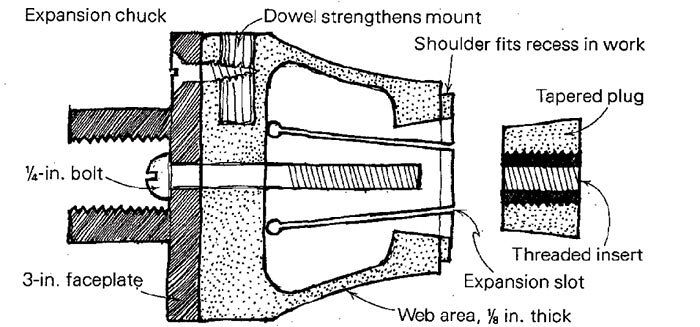

Expansion Chuck

I needed a lathe chuck to hold work without screw holes. This shopmade expansion chuck is invaluable for turning small trays, dishes and vases. A single 1/4-in. machine screw pulls a tapered wooden plug into a matching tapered section, thereby expanding the chuck and tightening it in a prepared recess in the base of the workpiece.

Make the chuck from a block of hardwood (I used Honduras mahogany) that has been permanently screwed to a small faceplate. Since the wood grain is perpendicular to the faceplate, install three birch dowels in the base of the block to increase the holding power of the mounting screws.

The overall shape of the chuck is somewhat arbitrary, but proper expansion can be achieved only if the webs are thin. After you have turned the outside to shape, carefully hollow the inside to give about 1/8-in. thickness to the web region. Fit the plug blank with a threaded steel insert, then turn the plug to match the taper of the chuck body. A 7 ¡ taper is about right. After turning is complete, drill stop-holes and cut eight expansion slots in the chuck body.

R.E. Hollenbach, Livermore, Calif.

Fine Woodworking Magazine, June 1982 No. 34

Fine Woodworking Recommended Products

Double Sided Tape

Incra Miter 1000HD

MicroJig Matchfit dovetail clamps

Log in or create an account to post a comment.

Sign up Log in